Essential Screen Printing Equipment for Business [2025]

Screen printing is one of the most common types of printing techniques used to produce bright and highly-industry prints on fabrics, paper, glass, ceramics, and other materials.

If you want to start a screen printing business, it’s a big jump. But with a true guru, it’s so worth it. For newbies who don’t know where to start, theprinterexpert.com is your hand with complete knowledge for printing essentials.

Having the right equipment is crucial for achieving high-quality results. After all, these must fit in your business and budget in the right way. This blog will guide you through the handy checklist of key pieces for screen printing equipment you’ll need to get started.

Top Screen Printing Equipment

To start a DTF printing business for T-shirts or garments, you must have the following equipment in your toolbox:

Screen Printing Press

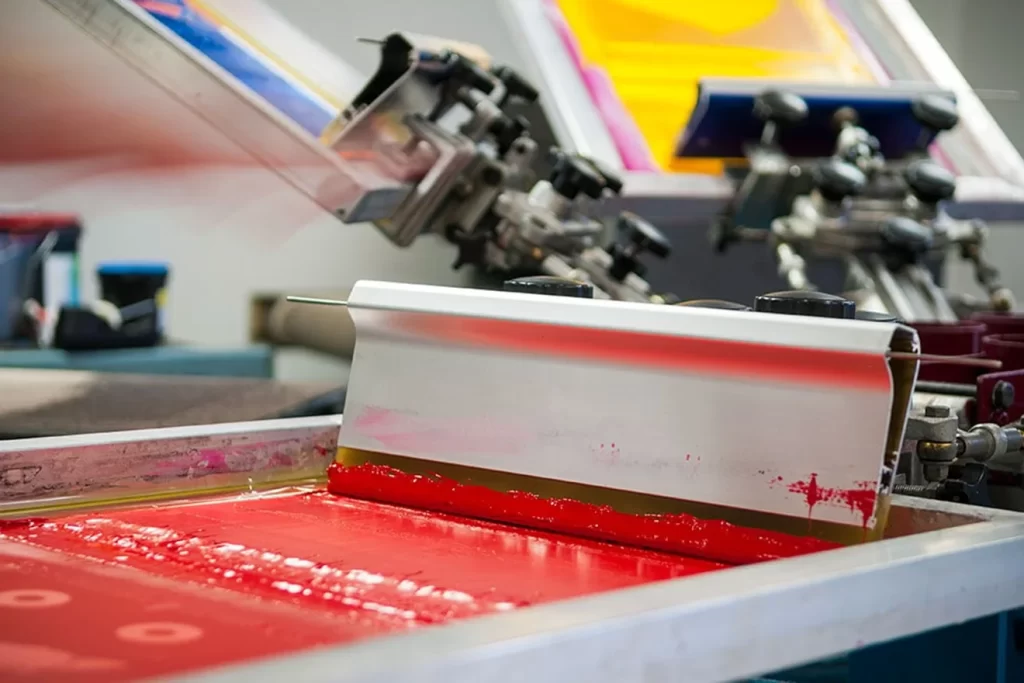

The first and foremost thing on your checklist is the screen printing press. It’s the heart of any screen printing operation. It’s impossible to screen print with just a mesh screen, you have to opt for a press for efficient printing.

The screen print press machine holds the screen in place for a precise ink application onto the substrate. There are several types of printing presses. All presses have different features, qualities, and prices. The choice depends on the volume of your printing project.

Manual presses are ideal for beginners and small businesses. They require manual operation and are typically more affordable. At the same time, automatic presses are suitable for high-volume production. The automatic printing process improves efficiency and consistency.

There is also a one-of-a-kind press known as a rotary press. It is typically used for continuous printing or cylindrical objects like bottles and cans.

![Checklist of Screen Printing Equipment to Start a Business [2024]](https://theprinterexpert.com/wp-content/uploads/2024/08/Checklist-of-Screen-Printing-Equipment-to-Start-a-Business-2024-1024x683.webp)

Screens and Frames

Screens also known as printing frames are of polyester or stainless steel. These are stretched over a frame to hold the stencil/mesh and sometimes the oil paint.

The higher the mesh count, the more accurately detailed the print will be on the fabric. These screen frames are constructed from aluminum or wooden materials and used to support the screen.

Squeegees

Squeegees help to spread the ink through the screen with tiny meshes and then apply it onto the substrate. Therefore, they have different shapes, sizes, and varying degrees of hardness suitable for a specific ink type and substrate.

Selecting the right one depends on the layout of the design to be printed, to avoid distortion or unequal ink distribution. A good-quality squeegee ensures smooth and even ink application.

Emulsion and Emulsion Coater

Emulsion is a light-sensitive liquid applied to the screen to create a stencil. Once applied, the screen is exposed to UV light with a design of transparency. The light hardens the emulsion, creating a stencil of the design.

An emulsion coater helps to apply a smooth and even layer of emulsion to the screen. Along with the emulsion coater, you have to keep an emulsion remover in your tool kit to emulsion off the screen before reusing it.

Screen printing Inks

When it comes to ink, the decision is really big. At its basic level, it sounds easy—and it is not. There are various types of printing inks; they differ in their applicability on a substrate or give a certain effect.

Plastisol is most commonly used for printing on fabrics. The motive behind that these inks are cost-effective to print, do not clog the screen, and come out with bright and durable colors.

On the flip side, if you’re looking for eco-friendly printing on light-colored fabrics, water-based inks are your best friend. But the downside with the inks is they will dry on the screen and will be much more difficult to reach proper curing.

Nowadays, the use of UV ink is a new trend in screen printing. This is because these offer more benefits than other types of inks. They cure quickly under UV light, suitable for printing on non-porous surfaces like glass and plastic.

Computer

A computer equipped with vector software comes next to your equipment checklist. In screen printing, people use vector art created with Adobe Illustrator or Corel. Some also use Photoshop, but it’s primarily for photography. So you’ll need a computer, either Adobe Illustrator or CorelDraw, as well as an inkjet printer.

You can print the inkjet film required to create the screens. To summarize, you only need a computer or laptop with good graphics, an inkjet printer, and vector software such as CorelDraw or Adobe Illustrator.

Flash Cure

The next thing on your checklist is flash curing. Screen printers use flash curing as a press when printing multi-color print jobs. A flash dryer is used to partially cure the ink between colors or layers. It helps prevent smudging and allows for multi-color prints.

When printing multi-color prints, it’s important to dry the inks to touch between prints. A conveyor dryer comes in handy to cure the ink fully, ensuring it adheres properly to the substrate. It’s essential for producing durable and long-lasting prints.

Another alternate curing method is heat pressing. A heat press is a more reliable and stable heat source than a flash dryer. You can read temperature fluctuations while using it. If you’re decorating shirts with DTG prints, you must use a heat press.

Exposure Unit

The exposure unit uses UV light to transfer the design from the transparency onto the emulsion-coated screen. Proper exposure is critical for achieving a crisp and accurate stencil.

People also use sunlight as an alternative to UV light. The problem with using sunlight is it’s not sure that even sunlight will be available every day (on cloudy and rainy days). Hence picking a UV light source like quartz and fluorescent tubes is best for you.

At some points, quartz light doesn’t provide enough UV light to harden the emulsion. And light fluorescents are also in the same boat. So, choosing the right light source is very important to increase printing efficiency.

Exposure units come in various sizes, from small tabletop units to larger industrial models. Some may start with an X1620 LED Exposure unit. If you have a budget, investing in an X1620 LED Exposure unit is a wise decision.

Washout Booth

Screen printing needs a washout booth while making screens. It is used to rinse out the unexposed emulsion after the screen has been exposed to UV light. This reveals the stencil and prepares the screen for printing.

Screens need to be cleaned after use to remove emulsion traces. This is done with a special cleaning liquid solution. Washout booths help contain water and emulsion residue, keeping your workspace clean.

Cleaning Supplies

Doing your DTF printer maintenance is as important as your home. It helps to maintain print quality and extend the lifespan of your tools. You’ll need:

- Screen Cleaning Chemicals: For removing ink and emulsion from screens.

- Scrub Brushes: To help clean screens and frames.

- Rags and Paper Towels: For wiping down equipment and work surfaces.

Choosing the Right Equipment

Selecting suitable screen printing equipment depends on factors such as production volume, print complexity, budget, and desired print quality. Consider the following:

- Production Volume: High-volume production demands automatic presses and efficient drying systems.

- Print Complexity: Detailed designs may require finer mesh counts and precise registration.

- Budget: Start with essential equipment and gradually expand as your business grows.

- Print Quality: Invest in high-quality presses, inks, and screens for exceptional results.

By understanding the role of each equipment component and carefully selecting the right tools, you can build a robust printing operation capable of producing impressive prints.

Conclusion

To run a successful business, you have to understand all the printing equipment clearly. The same goes for screen printing; you can’t compromise on the quality of essentials.

Well, if you have decided to dig into the screen printing industry, I’m here to save you from the hassle of being curious about the equipment. The above checklist is more than enough to get you started in the printing business.

If you’re starting from scratch and just want to upgrade the tools and equipment of your print shop, it will be very helpful to know what these pieces hold and for what purpose they are used.

The right equipment can make or break your business in real meaning. It not only delivers quality prints but helps to grow your business.