What is a DTG Printer? [2025 Edition Explained]

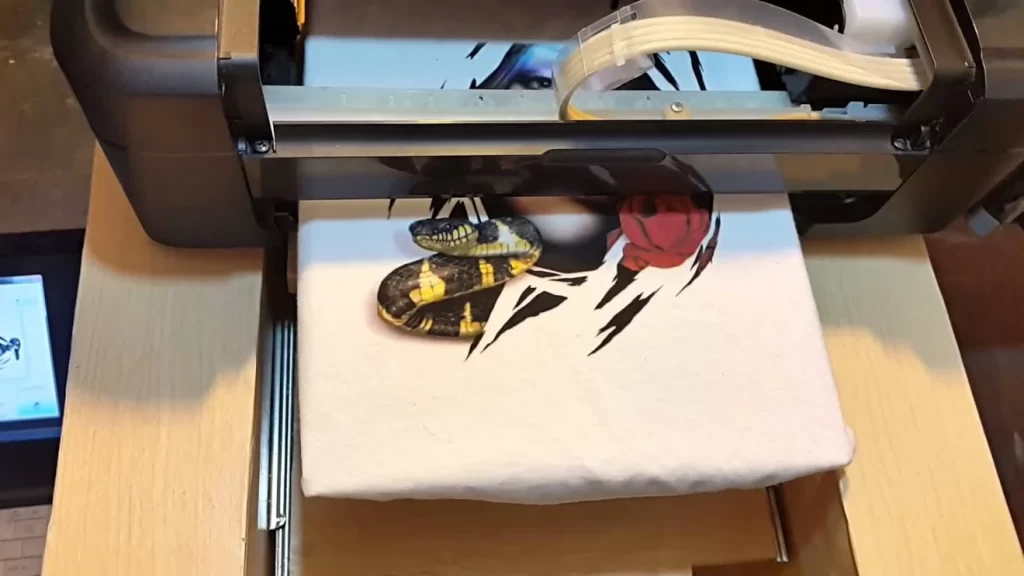

Have you ever come across a stunning t-shirt with a photorealistic design or a complex, multi-colored logo? Chances are, that t-shirt was created using a DTG printer.

DTG, or direct-to-garment printing is a revolutionary technology that allows for garments to be printed directly, much like printing on paper. But instead of ink on paper, DTG printers use specialized inks to create high-quality designs on fabric.

If you are new to DTG printers and want to know more about them, theprinterexpert.com will help you fuel your passion for exceptional direct-to-garment printing.

In this blog post, I’ll delve into what a DTG printer is, exploring its nitty-gritty details and why it’s a perfect solution for your on-demand printing needs.

Table of Contents

What is a DTG Printer?

DTG printers are the latest high-tech printing machines used mainly for printing textiles, such as t-shirts, hoodies, and tote bags.

DTG printing is way out of the league of traditional techniques like screen printing as seen, which requires you to develop screens for every color in the design. It simply injects the design into the fabric using specialized inkjet technology.

How Does a DTG Printer Work?

At the heart of a DTG printer lies advanced inkjet technology tailored for textile printing. Here’s a simplified breakdown of the process:

- Preparation of the Garment: The fabric to be printed like hoodies and t-shirts is pretreated for DTG with a special solution. This treatment helps the ink bond effectively with the fibers, ensuring vibrant colors and durability.

- Loading the Garment: The pretreated shirts for DTG are carefully placed on the printer’s platen (a flat surface), which holds it securely in place during printing.

- Printing the Design: The digital design, created on a computer, is sent to the DTG printer. Using specialized inkjet technology, the printer’s print head moves back and forth across the fabric, applying the ink in precise layers according to the design file. These inks are water-based and specially designed for textiles

- Curing the Ink: Once the design is printed, the garment goes through a curing process to set the ink. Depending on the printer and ink used, this can be done using a heat press or a specialized curing unit.

- Finished Product: After curing, the garment is ready to wear! The printed design is now permanently bonded to the fabric, resulting in a vibrant, high-quality finish.

Advantages of DTG Printing

DTG offers several advantages over traditional printing methods:

On-demand Printing

DTG printers excel at small batch printing, making them ideal for creating custom t-shirts, tote bags, or other garments printing work on demand. It’s easy to use and has less space requirement making it a more trending method in DTG printing.

There’s minimal setup time compared to screen printing, allowing for quick and faster production. This printing method is best for creating t-shirts or personalized merchandise.

Full-color Designs

DTG printers can produce high-resolution, full-color prints with intricate details. This opens up a world of possibilities for creative designs and photorealistic images.

With the printer, you can print the smallest detail with multiple color options. Also, you are not limited to the amount of color like screen printed, but there are endless options with DTG you have on a press.

Designs Flexibility

There’s no limitation on colors or complexity with DTG. Gradients, photo prints, and even text with fine details can all be reproduced with exceptional quality.

DTG printer gives an edge to designers with the flexibility to modify designs easily. Digital files can easily be uploaded, modified, and printed onto the fabric with minimal effort and time. This lets businesses quickly adjust designs based on customer feedback or market trends, keeping their products fresh and relevant.

Fast Turnaround Times

Today, where time is of the essence, people want quick printing results to run their business. Compared to screen printing, DTG offers faster turnaround times, especially for low-quantity orders. Since there’s no need to set up screens.

While cotton is the golden standard, DTG printers can also handle a range of fabrics, including polyester blends, making it a versatile printing solution.

Automatic Color Mixing

With DTG printers on hand, you do not need to mix ink colors manually. The DTG printer automatically mixes inks with CMYK and white ink. But the point is how it can benefit you.

It opens up multiple options for printing designs onto different types of fabrics that are impossible with other types of printing techniques.

Photorealistic Printing

The variation of colors available in DTG printing is wider compared to screen printing meaning that there are more variations in designs.

This include photorealistic designs that were not possible using the other forms of textile printing. By using automatic ink mixing, one can come up with slight gradients and produce a better image.

Eco-friendly

DTG inks are typically water-based and considered more environmentally friendly compared to solvent-based inks used in other printing methods.

This process also allows low energy consumption and minimum ink waste. The water-based inks are more sustainable and safe to use for even children.

Types of DTG Printers Available in the Market

DTG printers come in various types, each tailored to different needs and production scales. The right DTG printer for you depends on the nature and budget of your business. Here are the common types you’ll find in the market:

- Entry-level DTG Printer: This compact DTG printer is perfect for beginners and small business owners. Because it is easy to use, you can easily fix it in a home studio, gift store, and event sites. One of the budget-friendly printer options available in the market is the hrm A4 DTG T-Shirt printer machine and Multicolor DTG Printer. For limited space, the printer is assembled on top of a separate enclosed heating chamber for immediate ink drying.

- Mid-level DTG Printer: This DTG printer is a practical choice for a faster turnaround printing business. This printer is specially designed for medium-sized businesses with moderate production needs. It offers more enhanced print quality and speed as compared to entry-level options.

- Industrial DTG Printers: This printer is the best for print shops decorating bulk garments per hour at a lower cost than other commercial printers. Designed for medium-sized businesses with moderate production needs, this is the fastest printer ever to print a single shirt just in a few seconds.

Choosing the Right DTG Printer

When considering a DTG printer for your business or personal use, factors to consider include:

- Print Size: Ensure the printer can accommodate the sizes of garments you plan to print on.

- Print Quality: Look for printers with high-resolution capabilities for crisp, detailed prints.

- Fabric Limitation: DTG works best on natural fibers like cotton. While some pre-treatments allow printing on synthetic blends, the results might not be as vibrant or long-lasting.

- Cost Per Print: DTG printing can be more expensive per print compared to high-volume screen printing. However, for small-batch printing or customized items, the cost-effectiveness is undeniable.

Conclusion

DTG printers have seen a huge boom in the last decade. It’s a superb tool for printing on natural fabrics, polyester, and leather. Its full-color design, soft feel, and eco-friendliness make it a great choice for printing business.

If you’re looking for a versatile printing solution for on-demand projects, small businesses, or creating custom t-shirts, the DTG printer is definitely worth considering. Low setup cost makes it a breeze for tight-budget business.

So, what are you waiting for? Buy this masterpiece where your designs come to life on fabric with stunning clarity and vibrancy!