Types of Printing Techniques [Explained Guide 2025]

The history of print goes back a long way. Today, we are confronted with different types of printing techniques, all with their own specific purposes. Whether you are looking to print your company’s brochure, an attractive t-shirt, or a precise 3D design, there is no limitation to the printing method that fits your needs.

In this blog, I will talk about some of the most common different types of printing techniques, looking at their functionalities and ideal uses. Thus, it is time to choose your imaginative inkpad, and let’s start now!

Table of Contents

Different Types of Printing Techniques

The printing industry has involved so much with time. Some of the hottest printing techniques available in the market are the following:

- Digital printing

- Screen printing

- Offset printing

- Flexography

- Direct-to-film (DTF) printing

- Direct-to-garment(DTG) printing

- Gravure printing

- Letterpress printing

- 3D printing

- Sublimation printing

- LED UV printing

- Embossing and debossing

- Large-format printing

- Engraving

- Embroider printing

Digital Printing

The advantages of digital printing are endless, making it the king of versatility. It is pretty much a standard printing method to print postcards, newsletters, brochures, menus, and other print materials. It uses digital files (like PDFs) to transfer images and text directly onto various surfaces like plastic, paper, and even fabric.

This method cuts off on the physical print plates process, hence it is economical on short runs, quick turnarounds, and variable data printing (e.g. personalized mailers).

The two common digital printing technologies inkjet and laser printing offer high-quality output. Inkjets use some fine nozzles to spray ink droplets onto the surface, resulting in high-quality prints with brilliant color fidelity.

In laser printing, a laser beam produces an electrostatic image on a drum powdered with toner, resulting in neat and sharp business documents.

Pros

- Ideal for smaller printing needs, offering quick turnaround

- Cost-effective printing technique compared to offset printing

- Produce sharp images on compatible material

Cons

- Per unit cost increase for high-volume printing jobs

- Limited to types of paper they can print on

Screen Printing

Ever wondered how those cool graphic t-shirts get their designs? Screen printing is the answer! This technique also known as silk screening utilizes a stencil on a mesh screen to transfer ink onto a substrate.

It’s perfect for creating bold, vibrant prints on various materials, including textiles, glass, fabric, and even metal. This technique produces thick, opaque prints with a distinct tactile feel. It’s a popular printing technique to produce custom apparel, posters, logos, signage, and promotional items.

This printing method has high setups, not considered a cost-effective option for startups but good for printing repetitive things in large quantities. If you have a printing order in bulk to print the same thing, this printing technique is your go-to choice.

Pros

- Cost-effective for large-quantity printing orders

- Prints are known for their durability and vibrant colors

- Used on a variety of surfaces beyond fabric, including wood, metal, glass, and plastic.

Cons

- Setting up and cleaning screens can be messy

- Initial setup costs can be higher for small print runs

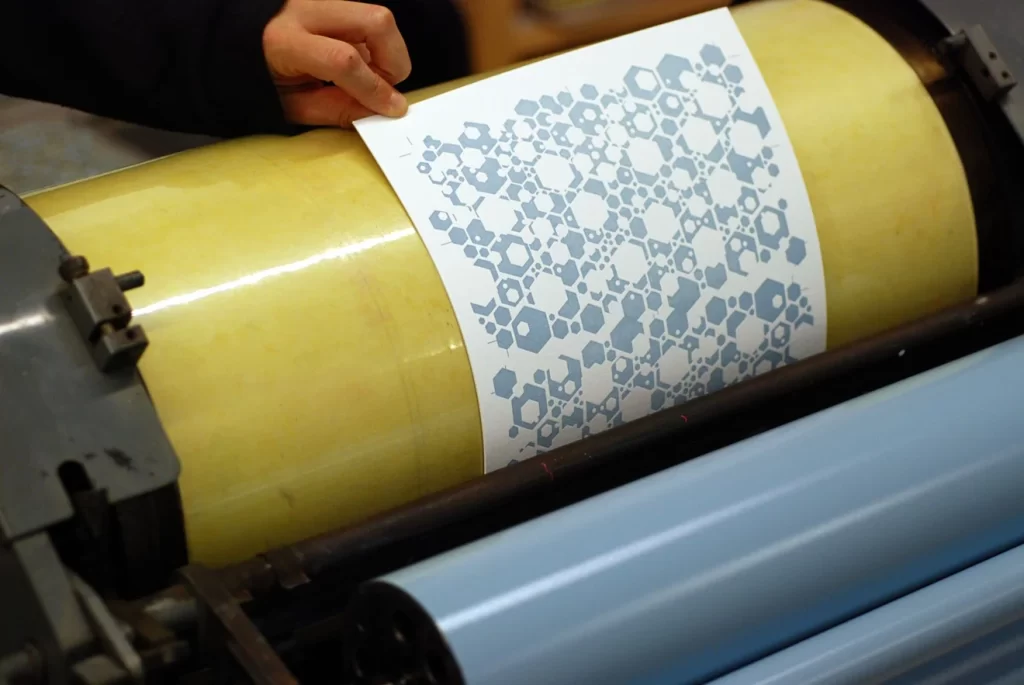

Offset Printing

Offset printing, also known as lithography, is a popular choice for high-volume commercial printing. Generally speaking, most printing businesses use this technique to print rough-surfaced items, e.g. canvas, wood, and cloth.

For large-volume printing projects like magazines, brochures, and packaging, offset printing takes the crown. It uses a series of plates to transfer an inked image onto a rubber blanket which is then pressed onto the final printing surface.

This printing technique delivers excellent color accuracy and consistency both on smooth and rougher surfaces, making it a popular choice for professional printing needs.

Pros

- Deliver high-quality prints with consistent color accuracy

- Cost-effective for high-volume printing runs

- Speedy prints, ideal for large print jobs

Cons

- Expensive and tedious setup for small businesses

- Not skilled people can handle this printing machinery

Flexography

Offset printing, also known as lithography, is a popular choice for high-volume commercial printing. Generally speaking, most printing businesses use this technique to print rough-surfaced items, e.g. canvas, wood, and cloth.

It calls upon the use of printing plates wrapped around a rotating cylinder to transfer ink onto various materials like plastic film and cardboard boxes.

This particular printing process employs the use of flexible photopolymer relief plates and fast-drying inks on non-porous materials like plastics, labels, and packages.

Flexo printing is famous for its speed, efficiency, and ability to handle thin, lightweight materials with high-quality detail and vibrant colors.

Pros

- Deliver vibrant colors and sharp images

- Fast and cost-effective for high-volume printing jobs

- Flexographic inks are known for their resistance to fading and wear

Cons

- Limited color accuracy for complex designs

- Not ideal for fine or realistic images

Direct-to-Film (DTF) Printing

Direct-to-film printing is the latest technique for printing on textiles. This process consists of printing designs on a special film, and then using a press heat to transfer to the target substrate.

As the name suggests DTF printers are used to print photos and patterns on almost any type of fabric. The type of printer you use greatly defines the success of your DTF printing business.

The unique printing method is rapidly becoming a popular tool in the fashion industry for its ability to print intense, detailed features on fabric with little minimal setup time.

Pros

- Deliver durable prints that ensure wash fastness and flexibility

- A good choice for smaller printing runs

- Work on a wide range of fabrics colors and materials, including dark fabrics and cotton-polyester blends

Cons

- Setting up a DTF printing setup at home can be complex

- DTF printing equipment and machinery require regular maintenance

Direct-to-Garment(DTG) Printing

Direct-to-garment printing is another innovative method to print directly onto garments using specialized inkjet printers. DTG printers are equipped with platens that are intended to hold the garment in one fixed position.

These printers have a print head that is used for spraying or jetting the inks onto the textile. This print technique is a perfect choice for artistic designs, and gradient shades, as well as a wide range of colorful branding t-shirts, polo shirts, bags, and sweatshirts.

Pros

- Deliver full-color designs, photos, and text directly onto garments

- Prints have a softer hand feel on the fabric

- Eco-friendly printing technique, saving the environment

Cons

- Per unit cost is higher for large print runs

- Pretreatment requirement before printing adds an extra step to the process

Gravure Printing

Gravure printing (known as Gravure) is a long-run, high-speed printing method that is used in printing lines. It is a type of engraving where rather than printing on a flat plate, an imprint is made on a cylinder (similar to that used in offset and flexography).

The cylinder is dipped in the ink, excess ink is wiped out and that cylinder is pressed onto the printing surface.

This technique is famous for its ability to precise pictures with bright colors being widely implemented in magazines, catalogs, banknotes, and luxury packaging.

One disadvantage you are facing while using this printing method is it is slow to set up and the initial price is higher than other printing methods.

Pros

- Exceptional print quality throughout the print runs

- Ideal printing technique for high-end packaging

- Work on a variety of materials, including paper, plastic films, foils, and metallic surfaces

Cons

- High setup cost, not suitable for small print runs

- Solvent-based inks are not eco-friendly

Letterpress Printing

Letterpress, once the primary printing method is the oldest one back to the 15th to 18th century. It involves pressing raised letters and images onto paper using inked type or plates.

The main complexity of this method is the arrangement of letters before stamping. To start the process, first, you have to decide on a suitable typeface. After that arrange and proofread the type before printing.

While less common today, letterpress retains its appeal for producing elegant, clear-cut prints with deep impressions. It’s favored for wedding invitations, stationery, and artisanal products.

One disadvantage of this type of printing is it takes time to create printing plates and set up the press. For multiple color prints, it’ll be expensive for you.

Pros

- Superb for printing short runs, resulting in a beautiful raised texture

- Creates a unique yet high-quality print on every type of compatible substrate

- Works on uneven surfaces as well as thick, high-quality paper stocks

Cons

- Need skills to print complex designs

- Not ideal for large print runs due to the manual setup and printing process

3D Printing

The new kid on the block is 3D printing. It isn’t technically a traditional printing method, but it has revolutionized the way we think about printing. Here, a digital file (a blueprint of a physical object) is used to build a three-dimensional object layer by layer using various materials like plastic or metal.

All 3D printers work in the same way. 3D printing opens doors for rapid prototyping, creating custom parts, and even printing prosthetics.

Over the last few years, this printing method has been taking a storm with more and more uses to produce novelty items, display items, toy figurines, promotions, and marketing freebies.

No one knows what we could see in the future!

Pros

- Create complex designs with precision

- Perfect for personalized printing projects

- Growing technique print on plastics, metals, resins, and even food-grade materials

Cons

- Expensive for large printing runs

- Energy consumption and hazardous materials raise environmental concerns

Sublimation Printing

This method uses heat to transfer a design from a special ink-filled paper onto a polyester fabric or coated surface. The sublimation ink transforms from a solid to a gas, fusing with the material for a vibrant, permanent print.

Sublimation printing gives fade-resistant prints. What’s great is these prints is they are also durable on fabric. It’s a popular printing technique to create custom sportswear, dishware, phone cases, mugs, and accessories like bags, pillows, and blankets.

It is not a versatile printing technology because it is only applicable to polyester or polymer-coated materials. Also, one drawback is it does not use white ink, hence it can only be used on white or light materials.

Pros

- Faster turnaround, perfect for on-demand printing projects

- Vibrant and long-lasting prints that won’t crack or peel over time

- Produce intricate designs and photos with sharp details and smooth color gradients

Cons

- Limited to polyester fabric and does not work best on cotton

- Process takes time and requires skilled knowledge

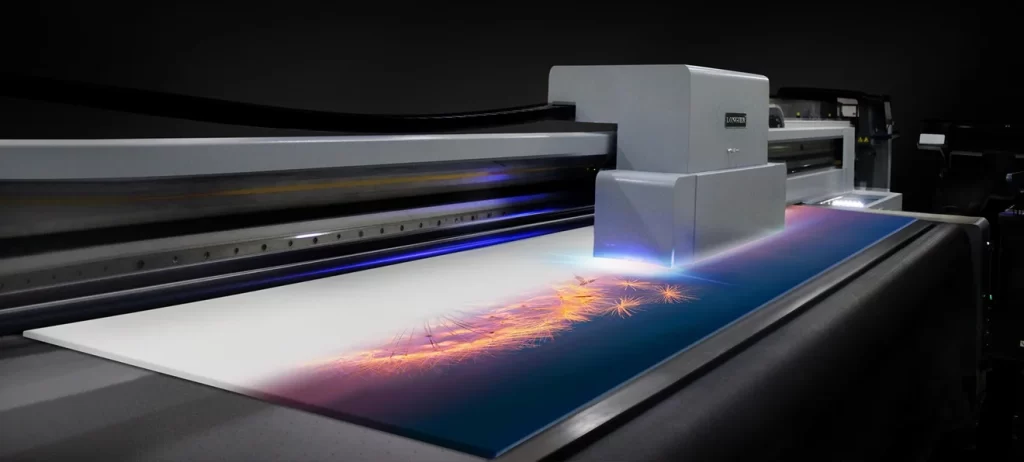

LED UV Printing

LED UV printing is one of the different types of printing techniques that are booming among businesses. The reason for this echo is high-quality prints and quick turnaround.

This innovative technique uses ultraviolet light to cure ink instantly onto the printing surface. This printing technique allows you to print on different materials, including unusual ones like plastic, wood, and even glass.

It’s an ideal method to create high-quality, durable prints for products, signage, newsletters, posters, stationery, leaflets, catalogs, magazines, brochures, and electronics.

LED UV turns an ordinary product into a luxury, high-quality finish without any mess. Another benefit is that this printing method uses less power than traditional printing.

Pros

- Less time-consuming as LED UV lights cure the ink instantly

- Produce excellent color gamut

- Can handle heat-sensitive materials like plastics, wood, and even canvas

Cons

- Higher initial costs due to high-end machinery and curable inks

- Limited substrate material thickness, may not handle thick material

Embossing and Debossing

Generally, both embossing and debossing have a lot of similarities. The sole difference lies in their finish. Both don’t involve ink but rather create raised (embossing) or sunken (debossing) designs on the paper.

These aren’t printing techniques in the traditional sense, but rather finishing techniques used as a combo with other printing.

These techniques add a touch of dimension and elegance to printed materials like business cards, invitations, and packaging. Ensure there is enough space between the letters while printing because these techniques can merge them.

Pros

- Create a sense of depth in the print designs

- Perfect for producing elegant and sophisticated prints

- Works on various materials like paper, cardstock, leather, and even metal

Cons

- Can be difficult to achieve intricate designs with embossing

- Thin or soft materials might not hold the debossed impression

Large Format Printing

Large format printing as the name implies deals with creating high-quality prints on massive surfaces. Think billboards, banners, building wraps, vehicle wraps, and even large-scale wallpapers. Some common techniques used in this printing are solvent printing, UV printing, and eco-solvent printing.

In solvent printing, solvent-based inks are used that are durable for outdoor use and resistant to fading. In UV printing, UV light is used to cure the ink instantly to print on various materials like vinyl, canvas, and even glass.

While eco-solvent printing is a more eco-friendly alternative to solvent printing with inks that offer good durability for outdoor applications.

This printing process, as opposed to other types of screen printing, such as digital printing, is perfect for conventional advertising mediums and businesses looking to make a lasting impact on their clients.

Instead of printing on individual sheets, big format printing uses rolls of prints that are fed repeatedly to make one big sheet. The majority of businesses employ large-format media to make flat things that can be displayed on a wall, but they can also be folded or made to stand alone.

Pros

- Create high-impact visuals that grab viewer’s attention

- Fast turnaround compared to other printing techniques

- Produce less waste, save the environment

Cons

- Higher setup cost, making it expensive for startups

- Professional printing skills needed to get best results

Engraving

Engraving is a subtractive process that carves a design onto a material using a sharp tool. The impression left behind gets imprinted forever with ink or paint. It enhances the contrast apart and leaves a more subtle result. This is something that only can be achieved using these kinds of techniques.

Common engraving techniques include laser, rotary, and diamond drag engraving. In the laser engraving process, a computer-controlled laser beam removes material very accurately and the rotary engraving technique involves the use of a rotary tool to engrave designs onto the material. Such an engraving technique is applied to cylindrical objects like rings and trophies.

It is considered the most expensive among different types of printing techniques. Also, it took a lot of time. When it comes to making royal invitation cards or business cards of high-ranking officials, engraving is the most commonly used printing method.

Pros

- Can print multiple colors in a one go

- Produce permanned and elegant prints, resistant to scratching, fading, or peeling

- Engraving can be done on glass, wood, plastic, and even leather

Cons

- Skilled artists needed to achieve precise results

- Slow process especially for detailed and complex designs

Embroider Printing

Embroidering isn’t quite printing in the traditional sense, but it’s a popular technique for creating designs on fabric. It uses a computerized embroidery machine to stitch thread patterns onto textiles.

Embroiders try to match the fabric hue color with the provided sample. This technique offers a unique advantage: three-dimensional, shiny, and lasting texture that gives elegant and durable prints.

People use it to adorn clothes, hats, bags, and other products made of fabrics, allowing for logos, lettering, and intricate designs in a variety of vibrant colors.

With embroidery printing, you should avoid an amalgamation of different colors. Choose the colors that best go with your product or offering.

Pros

- Designs are highly durable, resistant to fading and washing

- Can be done on wide range of fabrics, including delicate materials

- Allows for intricate details and a wide range of colors and effects

Cons

- Can be expensive, especially for complex designs and large quantities

- Not ideal for large-scale production due to the time involved

Choosing the Right Printing Technique

With so many options available in the printing world, selecting the right printing technique can feel overwhelming. Here are some key factors to consider while choosing the right printing technique:

- Project type: What are you printing? Brochures, t-shirts, or 3D models?

- Quantity: Are you printing a few copies or a large volume?

- Budget: Different techniques have varying costs per print.

- Material: What material are you printing on?

- Desired outcome: Do you need high-quality detail, vibrant colors, or a textured finish?

By considering these factors, you can choose from different types of printing techniques; the best one that suits your specific needs. Make sure you invest wisely and there are no regrets later on.

Final Words

The world of printing offers different types of printing techniques. Through this blog post, I have explored fifteen types of printing techniques to get quality print products for your business.

From high-volume, detailed offset prints to vibrant screen-printed t-shirts and innovative 3D creations, there’s a technique for every project.

So, the next time you need something printed, explore your options and unleash your inner printing guru!

If you want more clarity about printing techniques and different printers, theprinterexpert.com is the right place to get the desired final product and read more guides on printing.