Which epson printer can be converted to dtf?

DTF printing is a versatile approach to transferring intricate designs onto various fabrics. With the growing demand for DTF printers, one question often arises: which Epson printer can be converted to DTF?

It’s not all about which printer you have, it’s about what you do with it. While dedicated DTF printers are available, many individuals and businesses seek to convert their existing Epson printers for DTF printing to expand creative possibilities without breaking the bank.

Forget everything and focus on what I am saying now: the key to undoing the potential of your Epson printer lies in understanding its capacity for DTF conversion. With the right knowledge and tools, you can convert your printer into a powerful DTF printing machine.

Table of Contents

Which epson printer can be converted to DTF?

Epson, a renowned name in the printing industry, is known for its diverse range of printers catering to different needs. Not all Epson printers are suitable for DTF conversion. The key factor lies in the printer’s ability to handle pigment inks, which are essential for DTF printing.

Here’s a list of compatible Epson’s best printers to convert to DTF:

- Epson EcoTank L800: This popular model is a combination of affordability and quality. It offers high-resolution sharp prints with vibrant colors, making it a common choice for DTF conversion.

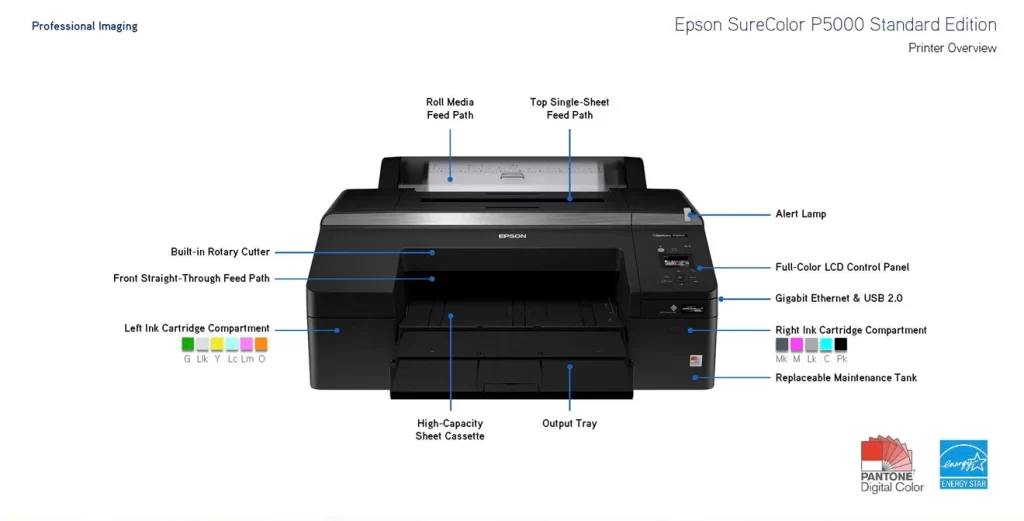

- Epson Stylus P5000: A robust printer known for its high-resolution printing capabilities, making it ideal for producing detailed DTF transfers.

- Epson EcoTank L805: Similar to the L800, the L805 offers a cost-effective option for DTF conversion without compromising print quality.

- Epson Expression Photo HD XP-15000: This versatile printer excels in both photo and DTF printing to deliver vibrant colors and sharp details.

- Epson Stylus Pro 4900: A professional-grade printer designed for high-volume printing, making it a suitable choice for businesses venturing into DTF production.

Plus, other Epson printers like P600, P400, L1800, L1300, and P6000 are used to be converted into DTF. These printers are equipped with the Micro Piezo printhead technology for superior color reproduction and present a solid foundation for the DTF conversion process.

Their compatibility with aftermarket modifications and enhancements has made them a favorite among users aiming to venture into the DTF printing domain. So, don’t be afraid and avail this opportunity. Be trendy by converting your Epson printer into an art machine that will lead you ahead of your competitors.

Steps for Converting Your Epson Printer to DTF

Converting an Epson printer to handle DTF printing involves several technical modifications and careful adjustments. Below is a step-by-step guide that provides an overview of the conversion process.

Although it’s advisable to seek professional assistance or guidance from reliable conversion kit providers to ensure the process is carried out smoothly and effectively.

Step 1: Select a Compatible Epson Printer

Start the process by selecting a compatible Epson printer model suitable for the DTF conversion process. Models like the Epson L1800 and L1300 from the EcoTank series are commonly chosen best printers to convert to DTF. This is just because of their adaptability to modifications and ability to handle specialized inks required for the DTF printing process.

Step 2: Gather Necessary Tools and Equipment

Collect all the necessary tools and equipment required for the conversion process. It includes the DTF conversion kit, which typically consists of an ink system, rip software, adhesive, heating element, and associated hardware. Ensure that all components are compatible with the selected Epson printer model.

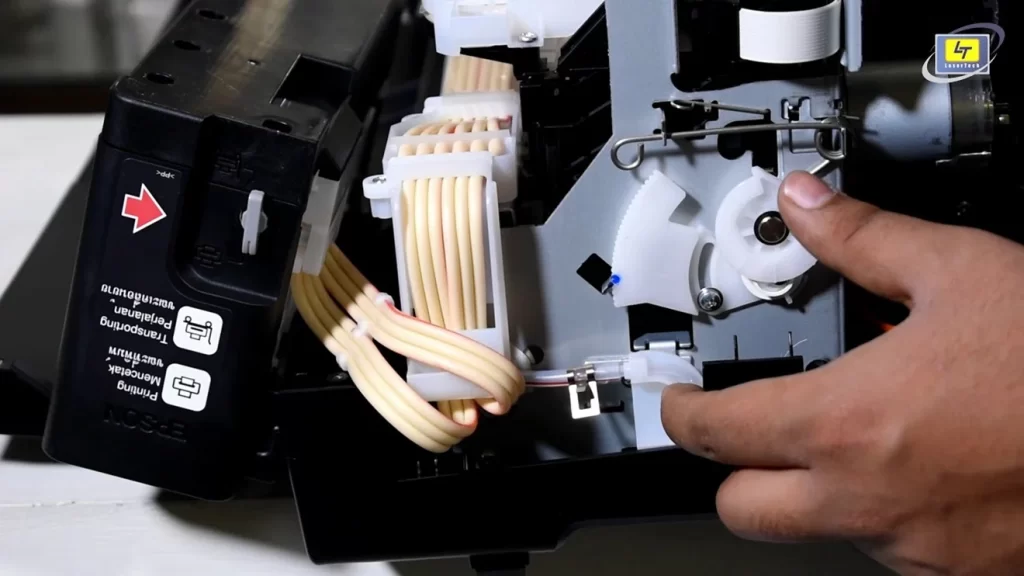

Step 3: Disassemble the Printer

Carefully disassemble the Epson printer, following the manufacturer’s guidelines and instructions. Take caution to avoid any damage to the printer components during disassembly. Keep track of each part and its position for proper reassembly.

Step 4: Install the DTF Conversion Kit

Install the DTF conversion kit components that involve the specialized ink system and the heating element, according to the provided instructions. The ink system includes ink tanks, bottles, or tanks to connect to the printer’s head. But make sure first to clean the print head manually. Check for tightness of every part so it remains firmly attached to the inner mechanisms of the printer.

Step 5: Modify the Printer’s Software

Modify the printer’s software settings and install the custom RIP (Raster Image Processor) software that is specifically designed for DTF printing. Adjust the settings to accommodate the requirements for printing on various fabrics and to enable the use of white ink as a base layer for vibrant prints on dark or colored textiles.

Step 6: Test the Modified Printer

Conduct thorough testing of the modified printer to verify its functionality and printing quality. Print test designs on different types of fabric to assess the printer’s ability to produce durable and high-quality DTF prints. Make any necessary adjustments or calibrations to ensure optimal performance.

Step 7: Reassemble the Printer

Reassemble the Epson printer carefully, following the reverse order of disassembly. Make sure everything is in place tightly without any problems. Fix everything, So it can work properly, no problem should happen.

Step 8: Repeat Printing Test and Fine-Tuning

Repeat printing tests, adjusting the printer settings to obtain the correct printing quality and uniformity. Adjusting ink flow, and temperature settings, among other parameters, is necessary if one wants high-quality outlines resulting from this technology.

By following these steps with precision and care, one can successfully convert an Epson printer into a reliable and efficient DTF printing machine. Give your old outdated printer a mid-life crisis and transform it into a style icon!

Challenges of Converting Epson Printers to DTF

Converting Epson into a DTF calls out to you sometimes. Some of the common challenges one faces are the following:

- Technical Expertise: The process of converting Epson printers to DTF requires a certain level of technical expertise. Without proper knowledge of printer mechanisms and DTF printing requirements, there is a risk of damaging the printer during the conversion process.

- Finding the Right Kit: Compatibility is key. Not all Epson models are compatible with DTF conversion kits. Ensure you choose a kit specifically designed for your printer model to avoid functionality issues or damage.

- Ink and Media Compatibility: Ensuring the compatibility of specialized DTF inks and media with the converted Epson printer is essential for desired print results. The use of incompatible inks or media leads to issues such as clogging, poor adhesion, or subpar color output, affecting the overall print quality and durability.

- Initial Investment: To convert a printer into DTF involves a start-up with special inks, films, and modifications. Investment is expensive and one might wait for a long time before reaping the benefits from it.

- Warranty Implications: Modifying the internal components of an Epson printer for DTF may void the original manufacturer’s warranty. It can pose a challenge, as any future issues with the printer may not be covered under the warranty, leading to potential repair or replacement costs.

- Calibration and Maintenance: Calibrating the converted printer for optimal print quality and maintaining its performance over time can be a challenging task. Regular maintenance, including cleaning of printhead and replacing consumables, is crucial for consistent DTF printing results.

Benefits of Converting Epson Printers to DTF

- Cost-Effectiveness: Converting an Epson printer for DTF printing is often more cost-effective than investing in specialized DTF printers. It makes it a viable option for businesses looking to expand their printing power without a substantial increase in initial investment.

- Versatility and Customization: Converted Epson printers offer a high degree of versatility for printing designs on various fabric types. The customization options include the use of white ink for dark fabrics, ceramics, plastics, and metal. It enables businesses to cater to diverse customer preferences and unique textile products.

- Enhanced Print Quality: Leveraging Epson printers’ superior print quality even after conversion ensures that the DTF prints exhibit vibrant colors, fine detailing, and long-lasting durability. This quality output contributes to customer satisfaction by delivering high-value, premium textile products.

- Durability of Printers: Epson printers are generally known for their robust build quality designed for long-term use. This foundation provides a solid base for DTF conversion. However, converting a printer to a different printing process introduces additional wear and tear on certain components, especially the print head. This is because DTF inks are thicker and more abrasive than traditional Epson inks.

- Faster Turnaround: DTF printing offers the ability to produce high-quality prints quickly, which can be beneficial for fulfilling orders with shorter deadlines. Converting the Epson printer to a DTF printer will streamline your workflow compared to traditional printers.

Understanding both the challenges and benefits of converting Epson printers to DTF is important to make informed decisions regarding the integration of this technology into printing operations.

With proper planning, technical expertise, and maintenance, you can score the benefits of converted Epson printers.

Tips and Suggestions for Successful DTF Printing with Epson Printers

Are you ready to play wild with your printer? All series of Epson and Stylus Pro are the best printers to convert to DTF. To get more exceptional results consider the following tips and suggestions:

- Invest in high-quality DTF inks that are compatible with a converted Epson printer.

- Make sure to adjust the printing parameters (resolution, ink level, color control) in the custom rip software so the printer performs best depending on the textile and pattern.

- Use compatible fabric gripping systems or frames to securely hold the fabric in place for precise printing. Make sure the fabric is tightly held during printing so the patterns do not go out of shape.

- Ensure proper curing (especially while using the white ink as the base coat). Considerate use of suitable heating elements like presses or ovens should be applied for the prints not to peel off easily as well as to have good resistance to washing off.

- Perform routine cleaning of printhead, check ink levels, and replace consumables as needed to maintain print quality and prolong the printer’s longevity.

- Carry out test prints on different materials to check the printer’s suitability and ink adherence. To have optimum results, one has to adjust print settings and curing process according to fabric types like cotton, polyester, nylon, or mix.

- Keep abreast of the latest advancements in DTF printing technology. Explore new software updates, ink formulations, and printing techniques to enhance the efficiency of DTF prints with converted Epson printers.

Cost-Saving Tips for DTF Printers

- Make the Most of Your Ink – Adjust your printer settings to use just the right amount of ink, to keep the print quality outstanding while cutting down on excess usage.

- Keep Up with Maintenance – Regular maintenance keeps your printer in top shape, avoiding pricey repairs and extending its life, which means more savings in the long run.

- Buy in Bulk – Stock up on supplies like film and ink in larger quantities to take advantage of discounts and lower your overall costs.

- Cut Down on Test Prints – Use digital previews to perfect your design before printing, saving on materials and avoiding wasteful trial runs.

- Invest in Quality Supplies – Spending a bit more on high-quality ink and the film pays off by preventing reprints and ensuring longer-lasting prints.

- Save on Energy – Consider energy-efficient printers or running your equipment during off-peak hours to lower your electricity bill while still getting the job done

Takeaway

While not all Epson printers are suitable for DTF conversion, the best printers to convert to DTF are L1800 and L1300 from the EcoTank series. With the right technical expertise and appropriate modifications, these printers can pave adventures in DTF printing successfully.

As the demand for customized textiles continues to grow, the conversion of Epson printers to DTF represents a valuable opportunity for those seeking to explore this vibrant and evolving industry. Look nowhere, go ahead champ!