DTF vs Screen Printing [Detailed Comparison 2025]

Hey there, fellow printing enthusiasts! If you’re looking to start custom clothing and wondering whether to go with Direct-to-film (DTF) or Screen Printing, you’ve come to the right place.

No matter if you’re a newbie or a pro in DTF and screen printing, theprinterexpert.com will help you fuel your passion for exceptional printing.

The crossroads of choosing the right printing method from different types of printing techniques for the upcoming project can be a daunting task. Although both printing methods have their own ins and outs, the key to choosing a suitable printing method is the one that connects with your brand and needs the most.

That’s why I’ve curated this guide to explore a side-by-side comparison of DTF vs screen printing for your better understanding of how they work. With better knowledge and clarity, you can determine which is more profitable to start your printing project.

Let’s dive into the nitty-gritty of these printing techniques to help you decide which one suits your style and business needs.

Table of Contents

What is DTF Printing?

Direct-to-film (DTF) printing is a relatively new printing technique that has been gaining popularity in the apparel industry. Unlike DTG (Direct-to-Garment) printing which inks fabrics directly, DTF creates a transfer first.

Your design gets printed onto a special film using a DTF printer inserted with pigmented inks. Then, that film with the design is heat-pressed onto your chosen fabric, be it cotton, polyester, or even blends.

This printing technique is commonly used to cater to small-batch printing orders, especially for T-shirt printing. It’s considered a cost-effective solution to print logos, slogans, and text on hoodies, bags, hats, and other garments. The prints you will get are of superior quality with a classy, fine-tuned look and durability.

How does it Work?

Now, let’s get into the meat of DTF printing. Follow the below steps to know how exactly DTF printing works to deliver vibrant designs.

Design Creation

First, your artwork is created digitally using RIP software, allowing for intricate details and full-color designs. Make sure the design supports DTF printing requirements.

Film Printing

Next, a DTF printer comes into action. It prints onto a specially coated film using vibrant, eco-solvent inks. Ensure the DTF printer supports the PET film and ink being used.

Drying

The printed film is set to a complete dry before proceeding. Make sure the ink is fully cured to prevent blotting during film transfer.

Powder Application

Once the design is printed on, sprinkle a thin and even layer of adhesive powder over the entire print. Shake off the excessive powder to remove any loose particles for a smooth finish. The powder sticks to the design and acts as a bonding agent.

Film to Fabric

Now your film design is ready to print on the fabric. It’s time to see the magic of a heat press machine. The film is placed onto the fabric and heat is applied using a heat press machine. The heat causes the melting of adhesive powder to bind the ink to the fabric.

Peeling

Allow the T-shirt to cool slightly before carefully peeling off the transfer film. With a gentle hand, peel off the film to avoid damage to the print.

Final Curing

Voilà! You’ve got detailed print ready to rock your garment. But for maximum durability, preheat the printed T-shirt for an extra 30 seconds. Set the shirt to cool completely before wearing it. You’ll see the print is like magic but with ink and heat!

Advantages of DTF Printing

Here are some advantages of the DTF printing technique:

- Vibrant Colors & High Quality: Prints sharp details with a wide color range.

- Versatility: Works on many fabrics (cotton, polyester, blends) and colors (light or dark).

- Durable Transfers: Wash well and resist cracking due to flexible inks.

- Faster Production: No pre-treatment needed, saving time on small orders.

- Lower Ink Usage: Less white ink is required compared to DTG printing.

What is Screen Printing?

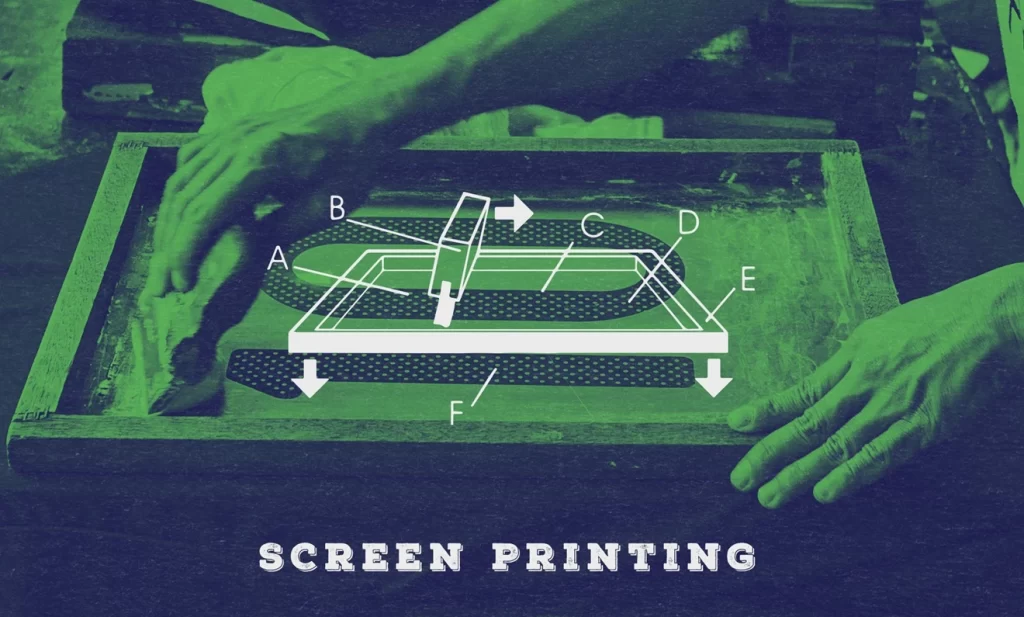

Screen printing also known as plastisol transfer is a classic technique that has been in use for decades. It involves creating a stencil (or screen) for each color in the design. Ink is then pushed through the stencil onto the substrate ( fabric, paper, or plastic) using a squeegee or heat press machine.

From cotton to denim, it gives a vibrant and consistent color gamut. This makes this printing technique ideal for simpler designs with limited color palettes.

Known for its durability and cost-effectiveness, screen printing is a favorite choice for bulk orders. However, the setup process is time-consuming for smaller print runs but will be beneficial in the long run.

How does it Work?

This versatile printing method is a bit more time-consuming. Here is a quick walkthrough of how screen printing works.

Design Creation

Create a digital design that you want to be printed. This design could be your artwork, logos, text, or image.

Screen Preparation

A separate mesh screen is created for each color in your design. This involves burning the design onto a light-sensitive emulsion coating the screen. It will lock off parts of the screen to allow ink to pass through in certain spots. It’s similar to crafting stencils for graffiti art!

Ink Application

Place the screen over the fabric and ink is spread over it using a blade or squeegee. The ink passes through the open areas of the screen, transferring the design onto the garment.

Color Layering

If your design has multiple colors, use a separate screen for each color and print layer by layer. It’s a bit slow but yields a vibrant durable result.

Drying

Set the ink to dry before moving to the next color layer. That’s how you will thoroughly complete the entire process.

Curing

Once all colors are applied, the fabric may undergo a curing process. It involves baking the ink onto the fabric using heat to set the ink permanently. This makes the print durable and long-lasting.

Advantages of Screen Printing

Here are some of the advantages of screen printing:

- Durable Prints: Screen printing creates long-lasting designs that resist fading and wear.

- Vibrant Colors: Opaque inks allow for rich and crisp colors that stand out.

- Bulk Order Friendly: Costs become lower per item as the number of prints increases.

- Versatile Application: Works on a wide range of surfaces, from fabric to plastic.

- Good for Various Inks: Enables unique textures and effects with a various ink application.

DTF vs Screen Printing: Side-by-side Comparison

Now, you have a better understanding of both printing techniques. Let’s get into the comparison of DTF vs screen printing to decide which one is better for your printing project.

Print Quality and Durability

In terms of print quality, DTF printing offers high-resolution prints with vibrant colors and smooth gradients. Due to the digital nature printing technique, the printed designs are full-color prints with intricate details and graphics.

Since ink doesn’t penetrate into the fabric, a single layer of print is very thin with a soft and comfortable feel. The transferred design becomes a part of the fabric, resulting in excellent wash-fastness and durability. Following proper DTF washing instructions, you can maintain their vibrancy and quality over time.

Screen printing also produces sharp, detailed designs with vibrant colors that stand out on garments. Colors tend to be more opaque and vivid, especially on darker fabrics. Plastisol inks ensure print color will remain bright and not fade over time or even after multiple washes.

Sometimes, you may struggle to produce fine lines and intricate details with this method. Because the print’s hand feel is heavy when dealing with large designs on dark fabrics.

When it comes to longevity, both DTF and screen prints are known for their durability. These prints can withstand regular washing and wear without cracking and peeling off.

Printing Speed and Volume

If you are in with small-batch orders, DTF printing is a profitable choice. It has a much quicker printing speed with a higher volume production. The lack of extensive setup like screen preparation streamlines the process, making it ideal for tight deadline projects.

And even, for last-minute modifications in design, this method can be adjusted easily. In short, DTF printing is the most popular printing method for easy-to-do orders on demand.

On the other hand, screen printing requires a longer time for set up like preparing the equipment and a specific screen just for the design. Each color in the design requires a separate screen — the more colors in the design, the more time-consuming for setup. This means it’ll kill time and resources for small-batch orders.

While screen printing might not have the same features as DTF printing, it’s still a viable option. Sure, it’s not as fast as zippy DTF, but the prints are incredibly durable and long-lasting.

Fabric Compatibility

DTF printing is quite versatile and you’ll be surprised to hear it can handle all types of fabrics. It includes cotton, nylon, fleece, denim, blends, and even some synthetic materials.

This is mainly due to the adhesive properties of DTF transfers that make a strong bond with different fabric types. One less thing to worry about, because your design will work nicely on almost any material.

While screen printing works best on natural fibers, mainly cotton and cotton blends. The plastisol inks used in screen printing bond well with these materials to ensure vibrant and durable prints.

However, screen prints don’t go very well on textured fabrics; ink adherence will be less reliable, affecting the durability of the prints. It lets you print on canvas, wood, metal, and even glass!

Cost Consideration

When it comes to which printing method is more cost-effective, people go out of their way to know the answer. But make no mistake, the cheapest option may not always be the best value… or… deliver the quality or durability you want.

DTF printing might not be the cheapest of the two, BUT…. it’s surely a cost-effective option in the long run. Look you don’t have to deal with screen preparation or cleaning of these screens every time you print. All you need is minimal equipment and setup time to turn around quality prints.

The initial investment may be a big one for small print runs but its efficiency and versatility for different fabrics are worth it. Here, you only ”buy once, cry once”.

On the other hand, screen printing may appear to have lower upfront equipment costs but it’s not always true. You’ve to deal with preparing and maintaining screens. It means you’ll need to invest time and money into making screens for each design you want to print. And it’s not a one-time — you’re in for a repeat.

Then there’s the cleaning of the screens. Another chaos you can’t avoid. The list goes on…it’s a classic case of “you get what you pay for,” but sometimes spending a little extra upfront might result in a lot of cash back later.

Nonetheless, screen printing becomes more cost-effective for large print runs since setup costs divide into a larger number of prints. It is commonly used in the garment industry for mass production and vinyl sticker printing because it provides low-cost solutions for large-scale orders.

Color Production

DTF printing uses digital technology, allowing for vibrant, detailed designs with a full spectrum of colors.

Since DTF prints use CMYK (cyan, magenta, yellow, and black) inks, they can create intricate color gradients, photo-quality images, and even small text with high precision.

You get great flexibility with color variation and blending, making it ideal for multi-color designs or complex artwork.

On the other hand, screen printing uses a stencil process for each color. Every layer of color requires a separate screen, which makes it less ideal for highly detailed designs with many colors.

However, for simple designs with a few bold colors, screen printing produces incredibly vibrant, solid prints. Since it uses thicker layers of ink, the colors often appear more opaque and rich, especially on dark fabrics.

Ink Types

DTF Print uses water-based pigment inks, designed for digital printing. These inks adhere to a special adhesive powder applied to the film, which is then transferred to the fabric using heat.

DTF inks are great for achieving vibrant color on various fabrics, and they allow for more detailed prints with subtle color transitions. The feel of DTF prints is usually soft and flexible after the initial transfer.

Screen printing typically uses plastisol inks (thicker and sit on top of the fabric) to create a slightly raised texture. They’re great for bold, solid colors and offer a longer-lasting print, especially on dark garments.

These types of inks are more lightweight and natural feel but may not be as vibrant on darker materials without special techniques like discharge printing.

Environmental Impact

Let’s speak the truth here — printing in general isn’t exactly eco-friendly. It is very energy-intensive: firstly it has to consume a huge amount of electricity to power machinery and equipment. Then, it demands fabrics, inks, and sometimes even chemicals.

Yet, that is not the only issue. You also have to ship these products to consumers, which burns fuel and adds to your carbon footprint. Ahh, and the waste!… But it’s not thoroughly hopeless, either. We’re slowly moving towards a greener future through innovations and new technologies in this space.

DTF printing produces less waste, as it doesn’t require the preparation and disposal of screens. By using water-based inks, you have got a sustainable option by your hand.

On the flip side, screen printing has a big problem with screen usage. Every time you are done with one color of design, you have to dispose of the screen for the next color that is not good enough for the environment.

Also, when you’re working with screens, you have to use chemicals and solvents to make and clean them. So, you can say DTF printing is more eco-friendly as compared to screen printing.

DTF vs Screen Printing: Which One is Good for Your Needs?

After knowing a detailed comparison of DTF vs screen printing, it’s obvious to say both printing methods have their ins and outs. When deciding to invest in a screen print press machine, I have some suggestions for you. Here’s a quick summary to help you choose:

Choose DTF Printing If:

- You want full-color, vibrant designs without additional setup costs.

- You want less setup and equipment investment.

- You are looking for high printing speed and quick print production.

- Your orders are smaller to medium-sized or on-demand.

- Versatility across different fabric types is important for your designs.

Choose Screen Printing If:

- You’re printing large quantities of garments for events, teams, or retail.

- Your designs are bold and straightforward with fewer colors.

- You appreciate the classic, textured look of screen-printed apparel.

Conclusion

In the battle of DTF vs screen printing, the right choice ultimately depends on your specific needs and preferences. Whether you’re leaning towards DTF printing or straight-to-screen printing, both methods have their perks.

Consider factors such as the design complexity, order size, longevity, texture, and budget when opting for the right tile. On the other hand, both have their own advantages, so be careful and think twice about which is most appropriate for your project goals.

Oh and another thing, spice it up! Try both printing techniques and see which of the two works better for your project. So, to sum it up, bear in mind that your clothes designs are a reflection of your style, so make them pop in whichever way feels right to you!