Dye Sublimation vs Inkjet Printing [Ultimate Guide 2025]

When it comes to creating vibrant, long-lasting prints, both dye sublimation and inkjet printers come to mind. Both printer inks might look the same to the untrained eye; as they are liquid. However, both printers have unique benefits, application processes, and limitations.

Choosing the right printer boils down to what you want to print and how you want it to look. If you’re debating between these printing methods, this comprehensive guide on “dye sublimation vs inkjet” will give you clarity.

If you’re new to any kind of textile printing, you’re not alone. Whether you have a dye sublimation, inkjet, direct-to-film (DTF), or direct-to-garment (DTG) printer, theprinterexpert.com is here to help you 24/7.

Here, I’ll unpack the differences between dye sublimation vs inkjet printing, helping you understand which might best fit your next project. No matter what you choose, I wish you the best of luck with your project.

Table of Contents

What is Dye Sublimation Printing?

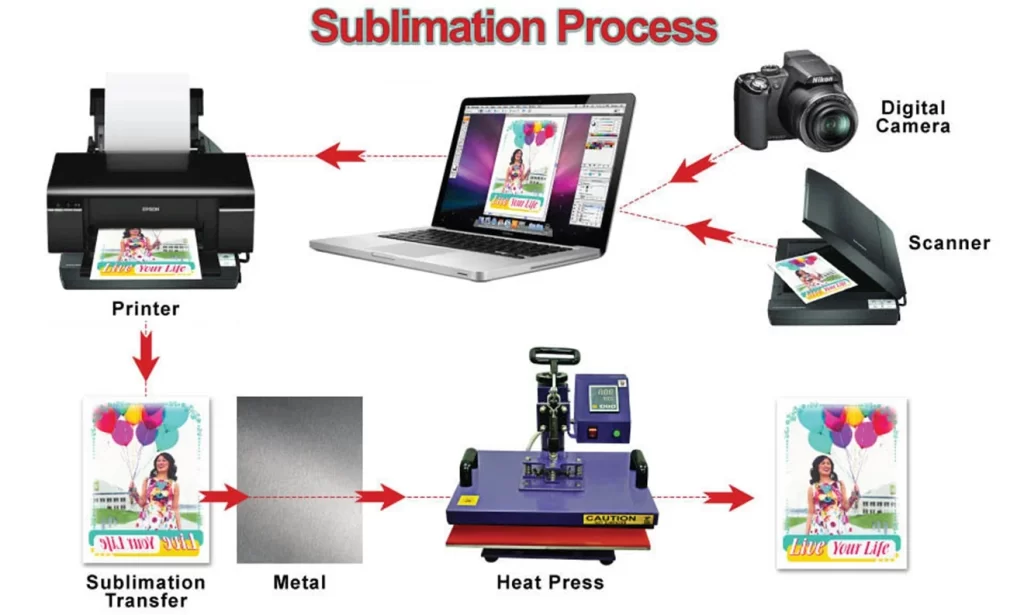

Dye sublimation is like getting a tattoo on your products. The process involves heat to transfer dye onto materials such as fabric, plastic, or paper. The design is printed onto a specialized Sublimation paper using sublimation inks.

The transfer paper is placed on the substrate (e.g., a polyester fabric), and heat is applied using a heat press. The heat turns the dye into gas without passing through a liquid state. The gaseous dye penetrates the fibers of the substrate to produce a soft feel durable print.

However, sublimation printing is best for fabrics with polyester or polyester blends. Natural fabrics, such as cotton, can’t sustain a lasting print. It’s also worth mentioning that this printing technique can cause white creasing when certain parts of the material don’t receive ink during the transfer, leaving blank spaces.

As the tech is blowing up, sublimation printers are booming in the market today. It’s a perfect printer to print on fabrics and tons of other items in a classroom setting.

Benefits of Dye Sublimation Printing

When choosing between dye sublimation vs inkjet, many people prefer the first one due to its immersing benefits. Furthermore, it is a quick method that lets you see results instantly.

- High-Quality Prints: Dye sublimation printing turns out high-quality prints with outstanding color precision. It can produce vibrant, full-color prints with photographic quality.

- Soft Feel: On fabrics, the print doesn’t add any additional layer, so the material retains its original feel.

- Versatility: Sublimation printing is ideal for printing on textiles, especially synthetic fabrics like polyester, and hard substrates(metal, ceramics) with a polymer coating. It’s a perfect option to produce personalized goods across different sectors.

- Durability: The dye becomes part of the fabric, making the print resistant to fading and cracking. These are highly durable and can withstand repeated washes without peeling off their polish.

- Cost-Effective: Although the upfront cost for sublimation printers is higher they are cost-effective in the long run. This is a reliable method to produce large volumes of quality prints.

Limitation of Dye Sublimation Printing

- Complex Process: Sublimation printing comes with a few limitations; one is its complex process. The complexity of the process depends on what you are printing on. It requires more knowledge and skills to precisely print on different substrates.

- Expensive Equipment: The equipment of sublimation printers is costly. If you want to produce larger items, you have to invest in large heat press and wide-format printer, which would definitely with a substantial price tag.

- Limited Range of Materials: While dye sublimation printing machines work on a wide range of materials, it is limited to polyester-based fabrics in their specialty.

- Limited Range of Materials: While dye sublimation printers work on a wide range of materials, it is limited to polyester-based fabrics in their specialty.

What is Inkjet Printing?

When choosing dye sublimation vs inkjet, the latter is much easier. The process involves spraying tiny droplets of liquid ink onto paper or other substrates. The ink droplets move through the printhead nozzles onto the substrate, where ink instantly dries and bonds.

Inkjet printers come in various types, including thermal and piezoelectric inkjet. Thermal inkjet uses heat to create bubbles that force ink out of the nozzle. While piezoelectric inkjet uses piezoelectric crystals to push ink out of the nozzle.

Paper quality highly impacts the output of inkjet prints. Coated papers are used to ensure precise dot placement and reduce stretching. Despite the detailed color gamut, individual color dots may distort at full view in inkjet prints. So, paper quality becomes a key consideration in this context.

Most inkjet printers use cyan, magnets, yellow, and black color inks to create a full-color spectrum. These printers are easy to use and affordable; that’s why widely used for offices, homes, and small business’s printing needs.

Benefits of Inkjet Printing

Inkjet printing has been in trend for a long time. Some of its benefits that make it an excellent option are the following:

- High-Resolution Prints: Inkjet printers are capable of producing detailed and high-resolution images. The text in the image will pop up with sharp details and vivid colors.

- Affordability: Inkjet printers are less expensive compared to sublimation printers, making them more affordable for small print runs and home use.

- User-Friendly: Inkjet printers are designed with customer convenience in mind. These are user-friendly, with easy installation and setup processes for small spaces. The wireless connectivity and intuitive control panel prove a hassle-free printing experience.

- Efficient Ink Usage: Inkjet printers are known to efficiently use the ink during the printing process. It means the printing process is satisfactory, saving ink and money.

- Versatility:Inkjet printers (like DTF printers) can print on a variety of materials including standard paper, photo paper, canvas, and even certain fabrics. You can handle multiple printing tasks, including, graphics, photos, and documents.

Limitation of Inkjet Printing

- Less Durable: Inkjet printers also have some limitation that makes them reconsider. As compared to sublimation printing, inkjet prints are not as durable and may fade away or smudge when exposed to moisture and severe weather conditions.

- Slow Printing Speed: Inkjet printers tend to be slower than sublimation printers. For bulk printing orders, it’s not a go-to solution.

- Maintenance: Inkjet printers require regular maintenance to run efficiently, including cleaning the print heads to prevent clogging and ensuring that the ink cartridges are properly inserted.

Key Differences Between Dye Sublimation vs Inkjet Printing

Because each technique has its pros and cons, you may now decide which printing process to use. However, knowing what makes them different and unique can help you make an informed decision on the best printing technique. Some key differences that both techniques show are:

Print Quality and Durability

The foremost thing to consider while choosing a printer is it’s print quality. In the debate of dye sublimation vs inkjet, dye sublimation wins the game. It turns into superior color vibrancy and durability, especially on fabrics. The DTF printing with sublimation inks is infused into the material and becomes part of the substrate. The prints are less likely to fade or crack over time.

While inkjet is capable of high-quality prints and wide color gamut but may not be as durable as dye sublimation prints. However, exposure to UV lights fades or smears inkjet prints if not handled properly. All thanks to the heat press; that temperature allows colors to blend very well during the sublimation process.

Color Vibrancy

Sublimation printers make prints with exceptional color precision because the dye sublimation ink penetrates deep into the material’s fibers, resulting in rich and bright colors that get ingrained in the material.

In contrast, while inkjet printouts produce a wide range of colors and detail, they may fade when exposed to UV radiation or over extended periods. This aspect can affect the print’s durability, making sublimation prints better suited for goods that must withstand the test of time.

Versatility

Sublimation printing and inkjet printing can work on a variety of materials but with some specifications. For example, sublimation printing lets you print on materials, including textiles such as polyester and rigid substrates such as ceramics, metals, and specifically coated items. This makes it a good alternative for enterprises that require printing on a wide range of materials.

On the other hand, inkjet printing is more suited to paper-based materials and it is widely used for photo printing and other related image printing on paper surfaces. Still, it is not as versatile as sublimation printing in terms of the materials used for printing, but it is a great solution for organizations that work with paper mostly.

Substrate Compatibility

Both printing techniques work on a wide range of materials but each has its own specialization. Dye sublimation is best for polyester fabrics and specially coated hard surfaces. So, it’s a fantastic option for businesses that need to print on mugs, metal glasses, textiles, and a variety of items.

On the flip side, inkjet printing is versatile in terms of materials, and capable of printing on strip paper, canvas, cards, and more. While not as versatile as sublimation printing in terms of material compatibility, it is a fantastic solution for businesses that primarily print on paper.

Efficiency

Efficiency is the main key that one weighs while selecting a printing technique. You fully want to ensure the printer is efficient and produces stunning results without problem.

With this in mind dye sublimation is generally considered more efficient than inkjet printers. The reason behind this is ink tends to be used less and produces fewer printing issues.

Despite its efficiency, dye sublimation printing may have slightly higher energy usage since it must supply power to the printhead to prevent clogging even when inactive. On the other hand, inkjet printing is less efficient as much ink is needed to print a page

Ink Composition

Besides the printing process, the ink composition of both printing techniques is different. Dye sublimation uses three colors: red, blue, and yellow. These three colors are more than enough to create hundreds and thousands of different shades.

Due to dye-based inks, the color formulation is highly vibrant and pops up due to its ability to penetrate the material.

On the flip side, inkjet printers use water-based inks that primarily contain four colors: cyan, black, magenta, and yellow. The pigments remain at the surface of the substrate. These prints have a duller finish as pigmented ink merely coats the surface.

Cost

In terms of startup cost, dye sublimation can be more expensive initially due to the cost of specialized equipment and transfer papers. However, ongoing costs and maintenance with this printing method are lower.

Inkjet is generally more affordable upfront, with a wide range of printers available at various price points. Keep in mind sublimation ink is affordable while inkjet cartridges run upward just for a few ounces.

Furthermore, sublimation ink shelf life is around 2 years, while inkjet inks degrade much faster. Head clogging and cleaning cycles needed with inkjet also bump up its operational costs.

So sublimation offers better value in the long run, despite higher initial capital investment. For businesses, the enhanced quality and durability justify the steeper startup pricing of sublimation systems.

Choosing the Right Printing Method

When deciding between dye sublimation vs inkjet, consider the following factors:

- Project Need: What are you printing? If you need durable, vibrant prints on fabric (mainly polyester, and its blends) or specialty items, dye sublimation is the way to go. For paper prints, photos, and general use, inkjet is more versatile.

- Volume: For large-scale fabric printing, dye sublimation is more efficient. Inkjet printers are better suited for smaller, more varied print runs.

- Material Compatibility: If you are to start a printing business on synthetic fabrics like polyester, nylon, and some blended materials, dye sublimation is best. While inkjet printing works best on paper, cardstock, canvas, and some fabrics (depending on the ink type).

- Print Durability: Dye sublimation Produces highly durable and water-resistant prints that resist fading and wear and tear. It’s ideal for applications like sportswear, phone cases, and outdoor banners. While durability with inkjet varies depending on the ink type and the material printed on. Inkjet prints on paper can fade over time, while prints on specific fabrics with specialty inks have good durability.

Conclusion

Both dye sublimation vs inkjet printing have their unique benefits depending on your needs. Dye sublimation excels in producing vibrant, durable prints on fabrics and specializes in polyester fabric, metal, and ceramic.

While inkjet printing is versatile, affordable, easy to use, and ideal for a wide range of everyday printing tasks. Choosing the right printing method depends on your project need, budget, and printing volume.

By understanding the benefits and limitations of each method, you can make an informed decision and achieve the best results for your projects.