Screen Print Press Machine [Beginner’s Guide 2025]

The world of apparel customization is vast and screen printing press machines are the backbone of coming up with good designs on different surfaces. Everything from a plain shirt with a bold design to a simple poster involves these press machines to transfer ink to any of these surfaces.

If you’re thinking about starting a screen printing business, then you must be in search of a screen print press machine. With so many options available in the current market, from budget-friendly small machines to mid-sized machines to large industrial machines it can be quite a challenge to select the right press.

But you don’t need to worry about all this mess, theprinterexpert.com is here to guide you along this printing journey. From picking a printer to any printing essential, there’s so much for you.

This blog will provide you with all the information you want about screen print press machines and how to select the right ones for your business or production.

Table of Contents

What is a Screen Print Press Machine?

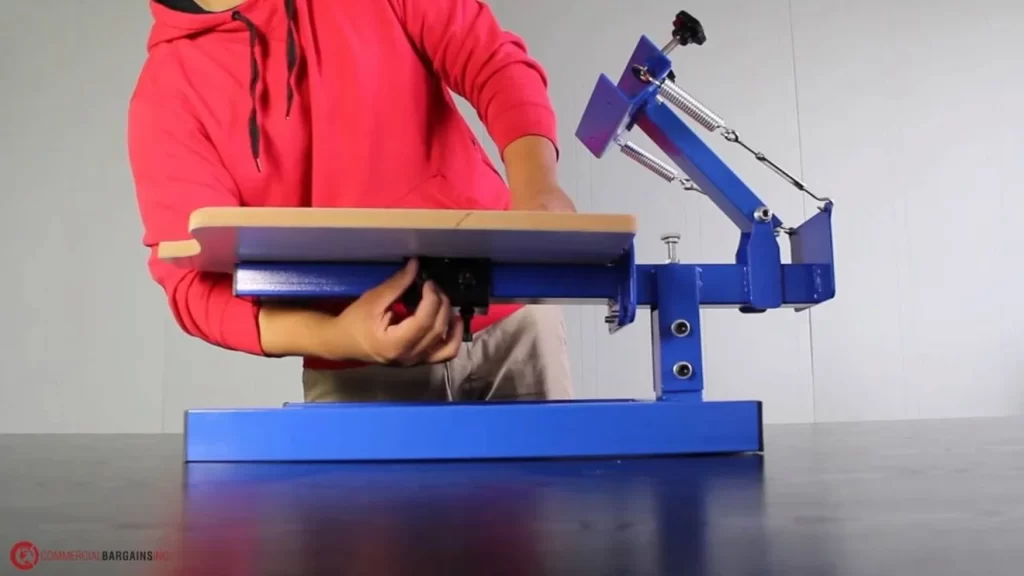

A screen print press machine is a device used to place ink on a substrate such as a t-shirt, a poster, or fabric through a screen. The process involves creating a stencil and applying layers of ink on the printing surface.

The stencil, also called the screen, has some areas that are made to prevent the ink from passing through them. It allows the press to push ink through the open parts of the screen making it possible to have detailed images on the substrate. This method is widely used to create high-quality long-lasting prints of a variety of fabrics.

Types of Screen Printing Press Machines

Screen printing presses come in various configurations to suit different needs and budgets. Here’s a breakdown of the main categories:

- Manual Presses: Perfect for beginners and small-scale projects, manual presses offer a hands-on approach. You control the squeegee (a tool that pushes the ink through the screen) and apply pressure to create the print. These are typically single-station presses, meaning you can only print one color at a time. Though it’s a budget-friendly option but has a slower production rate.

- Multi-Station Presses: As the name suggests, these presses allow you to print multiple colors in one go. Each station holds a different screen, enabling you to layer colors efficiently. These are ideal for production runs or projects requiring complex designs.

- Automatic Presses: For high-volume printing, automatic presses take the cake. These machines automate most of the printing process, from positioning the substrate to applying ink. While offering significant speed and efficiency, they come with a higher price tag and require more technical knowledge to operate. The upfront cost for an automatic screen press machine is high and requires more space.

Which Screen Print Press Machine is Best for You?

If you have limited printing orders, manual presses are more than enough. But if you want to take your print shop to the next level, you can’t do all the job by hand.

It’s time to switch to the automatic screen print press! You won’t compromise on quality and printing for hours ends in minutes now. It’s a big blessing in your shop for employees; who were used to pulling the squeegee for several hours.

Ultimately, an automatic press lets you expand your business. You can handle larger orders and complete them more quickly. With less time spent on press operations, you can focus on marketing your company and attracting new customers.

Benefits of Using a Screen Print Press Machine

- Cost-Effective for Bulk Printing: Ideal for large quantities, as the cost per print decreases with higher volumes.

- Versatility: Prints on various substrates like fabric, paper, glass, wood, and metal.

- Durable Prints: Produces vibrant and durable prints that can withstand repeated washing and usage.

- Infinite Color Options: Easily switch between colors for multi-color designs one after another with ease and precision.

- Space Saving: The compact design not only saves space but is also highly durable.

- Customizable: Easily adjust colors, designs, and substrates to meet specific needs.

- Portable: The suction cup feet attach to most surfaces; it makes it easy for you to move this press around. When you’re finished, hang it on a wall or keep it in a closet or cupboard.

Factors to Consider While Choosing a Screen Print Press Machine

Several factors come into play while selecting a screen print press machine:

Project Scale and Complexity

Consider how many prints you plan to make. For personal use or small projects, a manual press might suffice. But if you’re looking to delve into larger production runs, a multi-station press is a wise investment.

Printing Method

Manual presses require more physical effort but offer greater control over the printing process. Automatic presses are faster but might have a steeper learning curve. When you go to buy a screen print press machine, think about the printing method you want to opt for. The platen is the surface where you place the garment. Choose a platen size that accommodates your typical print sizes comfortably.

Budget

It’s no secret that money talks, so the first thing you should keep in mind is how much you want to invest in your screen printing press. Manual presses are often less expensive, making them an attractive option for startups and small businesses. However, it is essential to consider the potential ROI that an automatic press could provide in the long run, as they are more efficient and profitable.

Space Requirement

Think about the available space in your workshop for your screen print press machine. Manual and multi-station presses tend to have a smaller footprint and can easily move around. On the flip side, automatic presses are quite large and need more room for the set-up. Before you take the plunge, be sure you have enough area to accommodate your chosen press.

Maintenance and Support

Screen or DTF printer maintenance is the key to keeping your printing machine in good condition. Automatic presses typically require more upkeep than manual presses, so consider the time and expense of maintenance while making your decision. Consider the level of customer support and warranty provided by the manufacturer.

Tips for Beginners

- Start Simple- Begin with single-color designs to get the hang of the process.

- High-Quality Screens: Invest in well-made screens to ensure clean and consistent prints.

- Practice- The more you practice, the better your prints will become. Experiment with different inks on various substrates.

- Maintain Your Equipment- Regular cleaning and maintenance of your screen press print machine and screens will ensure consistent quality and longevity.

- Stay Creative- Don’t be afraid to experiment with new techniques and designs. Screen printing offers a lot of creative freedom.

- Research and Resources- Look for online tutorials, forums, and communities where you can learn from experienced printers and handle any issues you encounter.

- Safety First: Always wear appropriate safety gear, such as gloves and respirators, when handling inks and solvents. Ensure proper ventilation in your workspace to avoid inhaling harmful fumes.

The Takeaway

Investing in a screen print press machine opens up creative ways to personalize the bulk of products. From beginner-friendly manual presses to high-production automatics, there’s a machine to suit every need.

By considering factors such as project scale and complexity, budget, place requirements, learning curve, and maintenance and support, you’ll be well on your way to choosing the perfect press for your needs. Whether you’re working with different garment printing types, t-shirts for a friend’s birthday, or starting your own print shop, understanding the basics of screen printing will set you on the path to success.

So, now you are well-equipped to select the right screen printing press for your business. It’s time to get out there and conquer the screen printing business world!