Screen Print vs DTG: Which Printing Method is Right [Guide 2025]

Well, having the perfect design in your mind, it is time to let your vision be introduced on some cool tees. But with all the printing options out there, which one should you use?

Currently, there are many types of firing printing techniques in the market; however, the screen print vs DTG debate has been going on for quite some time now. Each one has its strengths and weaknesses and your best pick will be decided by your circumstances.

Selecting the right one would be the first step for the printing business. All this determines how you satisfy your customers, where you cut costs, and how to grow your business at the same time.

In this blog, I’ll explore the differences between screen print vs DTG to help you decide which method is right to make or break your apparel business.

Table of Contents

What is Screen Printing?

Screen printing, also known as silk screening, is a traditional method that’s been around for decades. It works by creating stencils on a fine mesh screen for each color in your design. It means your design is first broken down into different layers.

Next, a screen stencil is applied onto the garment at a time and then layer by layer onto the substrate. As more layers your design has, its feel becomes thicker. Ink is then pushed through the stencil onto the substrate (fabric, paper, plastic) resulting in a crisp, vibrant print that sits on top of the fabric.

Benefits of Screen Printing

- Best suited for bulk printing due to lower costs per unit.

- Produces long-lasting designs that resist fading and cracking.

- Achieves bold, vivid colors, especially on darker fabrics.

- Works well on a wide range of surfaces, including textiles and plastics.

- Allows for unique finishes like metallics, glitters, or puff prints.

What is DTG Printing?

DTG printing is a newer technology that takes a more digital approach. It works like a giant inkjet printer, spraying water-based inks directly onto the garment. The ink is then cured with heat to create a soft, breathable print that becomes part of the fabric.

The DTG method used colors out of cyan, magenta, red, green, white, and black. Not all designs use all six colors, most often CMYK is used to produce an intricate design. Instead of preparing a screen or paper for ink transfer, the printer directly applies onto the fabric.

Remember, a pretreatment spray is applied to the fabric before starting the process. It ensures the proper ink adhesion to the fabric. After pretreatment, the garment is loaded into the well-dedicated DTG printer, and the design is applied to the garment.

Benefits of DTG Printing

- Easily prints detailed, full-color images with gradients and shading.

- Ideal for small runs or one-off custom items without extra costs.

- Uses water-based inks, which are more environmentally friendly.

- Minimal setup required, allowing quick printing on-demand.

- Personalized individual prints with ease, such as names or logos.

Screen Print vs DTG: A Detailed Comparison

When deciding between Screen printing and DTG printing, understanding the nuances of each method is crucial. Here are specific features of both techniques to provide a comprehensive comparison.

Quality of Print

Whether you’re printing on a customized hoodie, t-shirt, sweatshirt, or tracksuit, the quality of prints is paramount to satisfy the customers. The hallmark of screen prints is its bright and vibrant colors due to the thick inks used. These inks are applied layer by layer to create a bold and vivid look, especially on light-colored garments.

With screen printing, each color requires a separate screen. This process is time-consuming and labor-intensive. However, the results in precise and consistent color reproduction, making it suitable for logos and simple designs with limited colors.

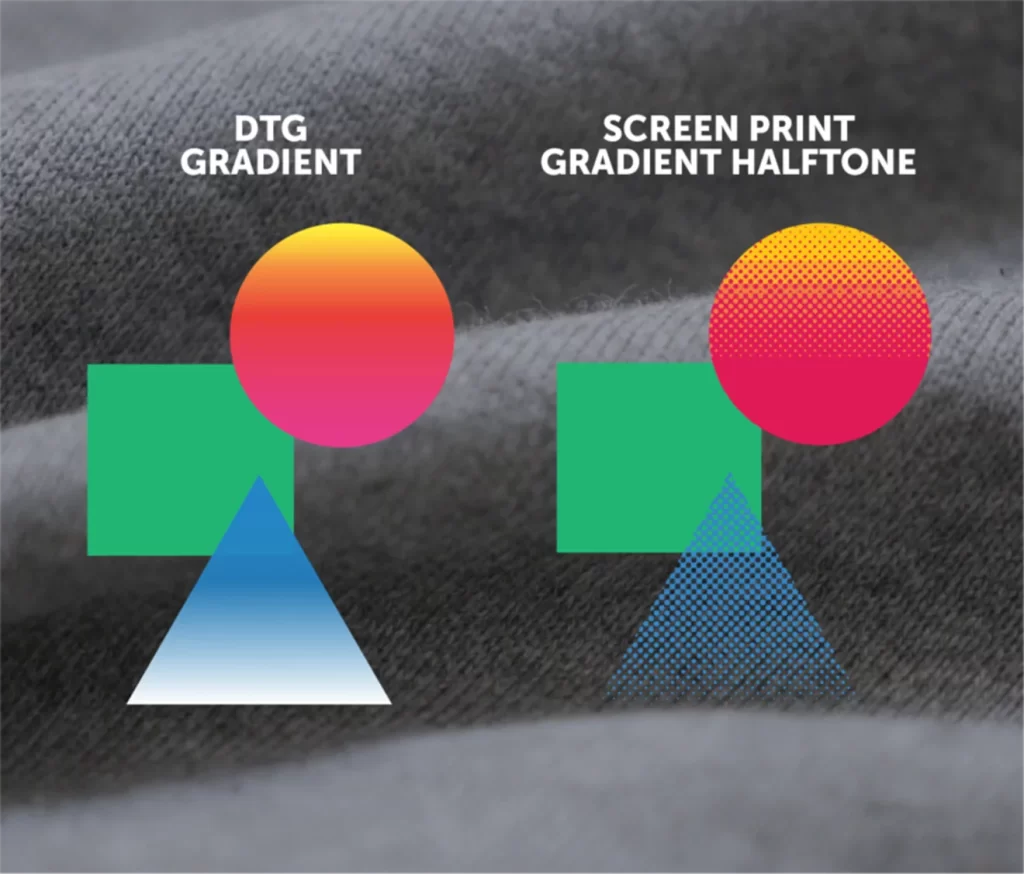

On the flip side, DTG uses CMYK (Cyan, Magenta, Yellow, and Key/Black) inks to mix colors on the fabric. This allows for a wide range of colors and is ideal for detailed images and photographs. DTG prints have fine details and smooth gradients, which are challenging for screen printing. This makes it perfect for complex and high-resolution designs.

Durability

In a modern throw-away society, people find durable prints more attractive. As these valuable products get hype, sadly it is rare to find them. The thick layers of ink used in screen printing penetrate deep into the fabric, making the prints highly durable.

People love these prints because they can withstand numerous washes without fading. These are also resilient to wear and tear, maintaining their integrity even after extensive use.

While DTG prints tend to be less durable compared to screen prints. Over time, and with repeated washing, the prints may fade or deteriorate more quickly. These are generally less resilient on fabrics that undergo heavy use or frequent washings.

Cost and Efficiency

Whether you’re thinking about new printing ideas or wanna scale up your printing business line, your foremost priority would be to choose a printing method that cost-effectively meets your business goal.

Screen prints cost a high initial setup due to the creation of screens for each color. This makes it less cost-effective for small runs or one-off items. Cost per unit decreases significantly with larger orders. That’s why this type of printing is ideal for bulk orders as the actual printing process will also get faster.

On the other hand, DTG printing demands minimal setup costs, as no screens or plates are needed. This makes it economical for small batches and single prints.

The process costs high per print for large orders compared to screen printing, due to the slower printing process and the cost of ink. That’s why DTG is ideal for on-demand printing services where quick turnaround is needed.

Design Complexity

In screen printing, each color in a design requires a separate screen, making it less suitable for designs with many colors or intricate details. Though, it’s excellent for maintaining consistency in large batches of prints.

But DTG printing is a better option to cater to complex, multi-colored designs with fine details. This includes photographs, intricate artwork, small text, and designs with gradients. This printing technology is ideal for custom prints and personalized items, allowing for greater flexibility and creativity.

Printing Speed

When it comes to printing speed, screen printing wins the game of large print runs. Though the preparation of stencils requires a longer setup time for multiple colors, its efficiency shines once the setup is complete. That’s why screen printing works best for bulk orders. A screen press printing machine can print up to 1,080 pieces per hour.

While DTG printing is slower than other printing methods, it’s perfect for on-demand printing orders. You can print just one piece without breaking your budget. Let’s say your studio relies on short-run orders, DTG printing is a go-to choice for you. Your customers will love this kind of printing because they will get their product without sacrificing over time and quality.

Fabric Compatibility

Screen printing can be used on a wide variety of materials. The only limit is your imagination. You can print on cotton, polyester, blends, and even non-textile surfaces like wood and metal. Customize t-shirts, bags, hats, and other clothing garments; posters, signs, mugs, phone cases, and laptop covers—the list goes on and on and your printing process never ends.

Most of the things around you have been printed via screen printing. It performs exceptionally well on dark fabrics, providing vibrant and opaque prints.

On the other hand, DTG printings work best on 100% cotton or high-cotton blends. However, it does not go well on metal, wood, and PVC pipes or acrylics. The quality of the print can vary on synthetic fabrics. Printing on dark fabrics with DTG requires a base layer of white ink, which can sometimes result in a thicker, less flexible print.

Environmental Impact

As a printing business owner, you have to be accountable for how your business affects the environment. Is it a sustainable way or not? With green living on the rise, sustainability has become the talk of the town.

Around 92 million tons of textiles go to waste every year. DTG printing offers print-on-demand service, offering a sustainable printing approach. It means a product is printed after being bought. DTG printing typically uses water-based inks that are less harmful to the environment.

These inks are eco-friendly compared to the plastisol inks often used in screen printing. Generally, energy consumption with DTG is low as the process does not require extensive setup or drying times.

On the flip side, screen printing involves the use of various chemicals for screen creation and cleaning. Excess ink and cleaning agents are harmful to the environment if not managed properly. Modern printing methods like DTG are improving with eco-friendly inks and waste management, but traditional methods still pose environmental concerns.

Comparing Screen Print vs DTG

| Features | Screen Printing | DTG Printing |

| Quality of Prints | High | Moderate |

| Durability | High | Moderate |

| Cost and efficiency | Cost-effective for large orders | Cost-effective for small orders |

| Design complexity | Less suitable for complex designs | Highly suitable for complex designs |

| Printing speed | Lengthy setup, high printing speed | No setup time, slower printing speed |

| Fabric compatibility | Compatible with cotton, polyester, blends, wood, and metal. | Work best on 100% cotton or high-cotton blends. |

| Environmental impact | Higher (chemicals and excess ink) | Lower (water-based inks) |

Screen Print vs DTG: What’s the Right for You?

The choice between screen print vs DTG largely depends on the specific needs of your project. Here’s a quick summary to guide your decision:

Choose Screen Printing if:

- You need a large batch of prints.

- You need simple designs with limited colors.

- Your design uses solid colors and is not overly complex.

- Durability and color vibrancy are top priorities.

- You’re printing on a variety of materials, including light-colored fabrics.

Choose DTG Printing if:

- You’re producing small batches or single items.

- Your design includes detailed images, photographs, or numerous colors.

- Quick turnaround and customization are important.

- You want detailed designs with full color on dark-colored fabrics.

- Environmental impact is a significant consideration.

Conclusion.

The best way to decide on the screen print vs DTG for your product is to identify what type of clients you have. Therefore, when comparing the two printing options, consider the specifics of your order, including quantity, design complexity, and desired durability,

If your business requires many shirt printing, then you ought to go with the former option. However, if you have the on-demand printing t-shirts, then go for the latter one.

DTG printing has more profit margin on small custom orders there can be no setup fees at all while screen printing can give a 70 % margin on large bulk production.

Now that you know the differences between the two methods, this will ensure you make the right decision when it comes to fulfilling your needs for custom t-shirts.