Types of Offset Printing | Comprehensive Guide [2025]

Offset printing remains a dominant force in the printing industry, renowned for its ability to produce high-quality prints at scale. But beneath the umbrella term “offset printing” lies different types of offset printing, each with its pros and cons.

Whether you own a printing business or are a layman who wants to learn types of offset printing, you have come to the right place for the printing expert.

Let’s wear your fancy glasses to delve into the different types of offset printing, equipping you with the knowledge to choose the most suitable method for your next project.

Table of Contents

Types of Offset Printing

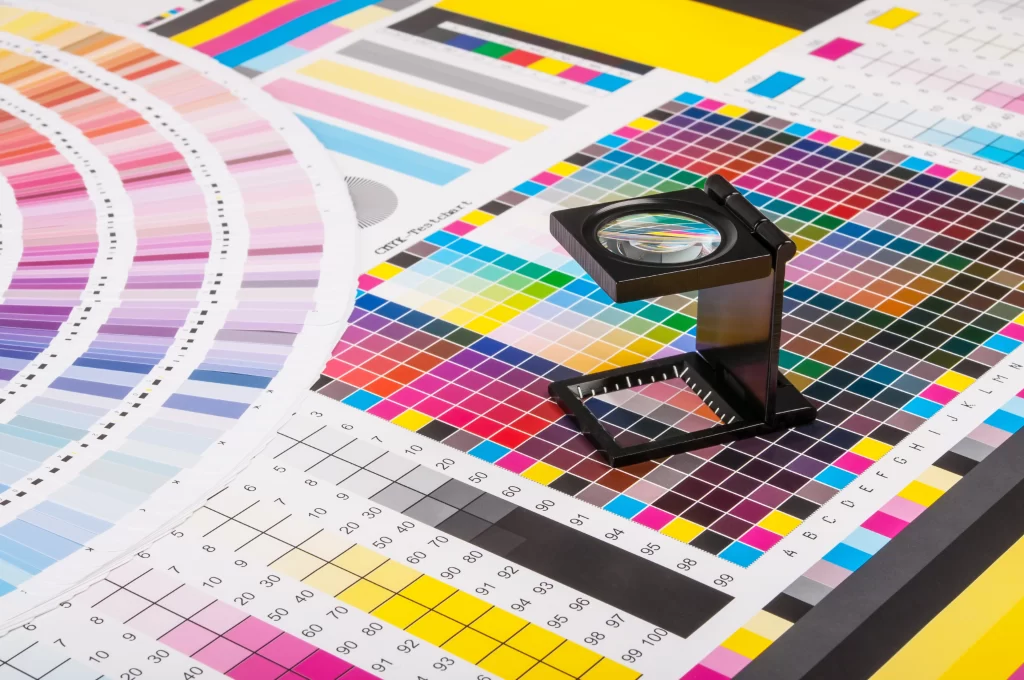

Offset print (also called offset lithography) is a printing technique in which the ink is transferred using a rubber blanket from the printing plate to the printed surface. This method was introduced over a century ago and up to date used for various prints purposes.

It works based on the rule that oil and water never mix. It is done by a set of rollers transferring the image on the printing surface. This printing process is used to print brochures, flyers, business cards, stationery, packaging material, books, and magazines.

When it comes to types of offset printing, everyone gets curious to know. It not only helps them in choosing the best DTF printer for their business but money comes in fruit. Two main types of offset printing are the following:

Sheet-fed Offset Printing

Sheet-fed offset printing is used for printing individual sheets of paper. This type of printing usually applies to smaller print runs, such as business cards, brochures, and flyers. The steps in this printing process are as follows:

Step 1: Preparation- Before the printing process starts, a bit of preparatory work is required. It involves the process of printing such as the assembly of a press, and selection of the right ink and plates.

The printing plates are a key element of sheet fed offset printing. These plates are normally made of aluminum. The image or text to be printed is engraved in them. They are mounted onto cylinders on the printing press.

Step 2: Feeding- One of the standout features of sheet-fed offset printing is its sheet-by-sheet feeding mechanism. Individual sheets of paper are manually or automatically fed into the press.

The sheets are carefully aligned and positioned to ensure precise printing. Registration marks and sensors help to maintain the accuracy of prints.

Step 3: Printing Process- The printing papers go through the press between the rollers arranged in a series. They apply ink from the ink rollers to the printing plates. The ink is put only onto those parts of the plates that have the image or text.

Technically, the process of sheet-fed offset printing is based on the idea that the oil-based ink sticks to the image parts while the water doesn’t adhere to them.

Step 4: Inking and Watering- The ink rollers carry the ink while the dampening rollers apply water to the areas of the printing plates not carrying the image. This process is known as the “offset” principle.

The inked areas on the plates transfer the image or text onto a rubber blanket cylinder. This rubber blanket then presses the image onto the paper sheet to leave a clean and precise print.

Step 5- Drying and Delivery– After the printing, the paper sheets proceed to a drying unit or conveyor, depending on the press’s configuration. Here, heat or air is used to dry the freshly printed sheets to prevent smudging or smearing.

Finally, the printed sheets are neatly stacked and ready for further processing, like cutting, binding, or packaging.

Pros

- High-resolution prints with sharp colors

- Employ sensors for precise alignment of prints

- Cost-effective option for short to medium print runs

- No set-up cost with a higher production rate

Cons

- Printing speed may be slower than other types of printing

- Not an economical choice for very large print quantities

Web Offset Printing

On the other hand, web offset printing is the best choice for high-volume printing. Rather than using individual sheets, these types of offset printing employ big rolls of paper for printing on cardboard boxes, newspapers, magazines, and catalogs with great efficiency. The continuous feeding mechanism ensures faster output. Following are the steps involved in this printing:

Step 1: Preparation- This process starts with the prepress preparation phase. This includes designing and typesetting the content required for printing and making the printing plates.

Usually, they are made of aluminum and with CTP technology a print plate with a picture or text is prepared.

Step 2: Paper Roll Feeding- Web offset has pre-fed paper rolls instead of individual sheets. At press, these rolls are loaded. The paper passes through a series of rollers and tension controls to make sure that it is aligned and tensed appropriately.

Step 3: Printing Units- The printing process consists of printing units, each unit having its own set of printing plates and cylinders. The ink is evenly distributed over the printing plates and the paper gets printed by passing through the printer plates and an impression cylinder. The printing plate is inked, then the paper is printed.

Step 4: Paper Drying- The printed paper goes through a drying system to prevent smudging and fast drying. For this purpose, heat lamps or hot air are commonly applied. The drying process is a major factor in quality maintenance and prevention of the ink from being transferred to other pages.

Step 5: Color Printing- With web-offset full-color (CMYK), ink units are used to produce colors one after the other with features of registration accuracy (cyan, magenta, yellow, and black). Registration marks and sensors will ensure that each color layer is aligned accurately with all others to make a full-colored image.

Step 6: Finishing- After printing, a piece of paper may go through cutting, folding, binding, and trimming that depending on the final use of the finished product. This stage completes the product which could be a newspaper, magazine, or catalog from the rolls of paper.

Pros

- High-speed production

- Cost-efficient for a print run in bulk

Cons

- Longer lead time for setup and plate changes

- Print quality is lower than sheet-fed

Benefits of Offset Printing

Quality: Offset printing is known for making brilliant prints with bright colors, clear images, and an even surface. The process involves transferring the ink via a plate and then rolling it onto a rubber blanket before touching the paper in order to produce quality prints.

Cost-Effectiveness: Interestingly, getting the first set of offset prints may be costly compared to digital prints for small quantities. This saves on the cost per unit when many copies can be printed at the same time, which makes it suitable for large scale production.

Environmental Friendliness: This printing technique has become more environmentally friendly in recent years. Advances in technology and the use of eco-friendly inks and recycled materials have reduced the environmental impact of the process. Additionally, offset printing often allows for better waste management and resource conservation compared to other printing methods.

What is Digital Offset Printing?

Digital offset printing is a modern, versatile, and standalone printing technology – independent of the types of offset printing. The process merges the perks of digital as well as offset printing. In this technique, the image or text to be printed is loaded from the computer to a printing plate, just like what is done in traditional offset printing.

Nevertheless, the digital printing process does not require physical printing plates for each color as it uses high-tech digital technology that applies the ink directly onto the paper or other printing media.

This not only allows for high-quality, consistent prints with sharp details and vibrant colors but also offers the flexibility to customize each printed piece for short to medium print runs and projects that require personalization.

This in turn gives you the ability to provide high quality, good consistent prints with the sharpness of details and the brilliance of colors which can then be customized to fit within a short to medium print run and projects that require customization.

Because of the endless advantages of digital printing, it’s gaining popularity among businesses looking for budget-friendly, print-quality of the highest standards, yet fast turnaround times and little setup requirements

Choosing the Right Type of Offset Printing

“In any walk of life, you can choose to do the right thing”. Same as choosing the best types of offset printing is mandatory. It’ll depend on your specific needs like the type of material you are printing on, the volume you need to print, and your budget.

If you are printing on individual sheets of paper and need a smaller print run, then sheet-fed offset printing is a good option. If you are printing on large rolls of paper and need a high-volume print run, then web offset printing is a good option.

If you are still unsure which type of offset printing is right for you, then it is best to consult with a professional printer.

Conclusion

No doubt offset printing is for businesses who need high-quality prints. No matter if you choose sheet-fed, web, or digital, all types of offset printing have their own advantages. Understanding these choices helps you to make an informed decision for your next printing project.

Thanks to offset printing’s excellent quality, affordability, and flexibility you’ll have no difficulties meeting the needs of your clients by producing outstanding printed materials.