UV DTF Printer | Game-Changer in Textile Printing [2025]

In the fast-paced world of printing technology, the UV DTF printer has changed the way we print and design. The world is changing quickly and we must be ready to mold with it or risk being left behind.

This innovative technology is taking the printing industry by storm for unparalleled print quality and versatility. It’s gaining popularity among businesses and hobbyists alike, and many retailers now offer UV DTF printers for sale.

If you’re looking to lift your printing game to the next level, look no further than using the UV printer. This post will help you to know about what it is, how it works, its applications, and why it’s becoming increasingly popular in the textile industry.

Table of Contents

What is a UV DTF Printer?

A UV DTF printer, or ultraviolet direct-to-film printer, is a type of digital printer that uses ultraviolet curing technology to print directly onto a special film. This special DTF film is then transferred onto a variety of materials, including wood, metal, plastic, glass, and even fabric.

Due to its versatility, precision, cost-effectiveness, durability, and high-quality designs, this technique is termed the “smarter printing choice”. Enabling mass production in a short period, this method is revolutionizing the textile industry.

When you purchase a UV DTF printer, you invest in a versatile and efficient tool that uses UV ink technology for instant curing, resulting in durable and precise designs.

These printers typically come with user-friendly software, allowing even beginners to create professional-grade transfers. It’s the same as a powderless DTF printer in the market.

With various models available, ranging from compact desktop units to larger industrial machines, there is a UV DTF printer to fit every budget and production need. It’s an excellent addition to any printing business or creative studio.

How Does it Work?

Step 1: Inkjet Technology

UV DTF printer Epson, or no matter other brand utilizes advanced inkjet technology to deliver precise and vibrant prints. It uses UV-curable ink that is cured or dried instantly using ultraviolet (UV) light.

Step 2: Film Application

A thin, transparent film is applied to the fabric before printing. This film acts as a medium for the ink and ensures that the colors stay true to the original design.

Step 3: Printing

The UV printer then applies the ink directly onto the film, which absorbs it quickly. The UV light cures the ink to give out durable and long-lasting prints.

Advantages of UV DTF Printer

Using a UV DTF printer for small businesses, you can avoid many printing problems linked with DTF. It offers several advantages that have made it a preferred choice in the textile industry:

Durable Prints

UV DTF printers are known for their durability, making them an excellent choice for applications requiring long-term use. The UV-cured inks used in this method are very resistant to fading, cracking, and peeling, so your prints will remain brilliant even after repeated washing or exposure to harsh environment.

Versatility Redefined

The UV printer isn’t limited to just fabric printing; its versatility knows no bounds. From cotton and polyester to leather and canvas, this printer can handle different materials. Using this printer, no matter whether one is a fashion designer, merchandise, or runs a printing business, opens up great opportunities for exploration.

Highly Resistant

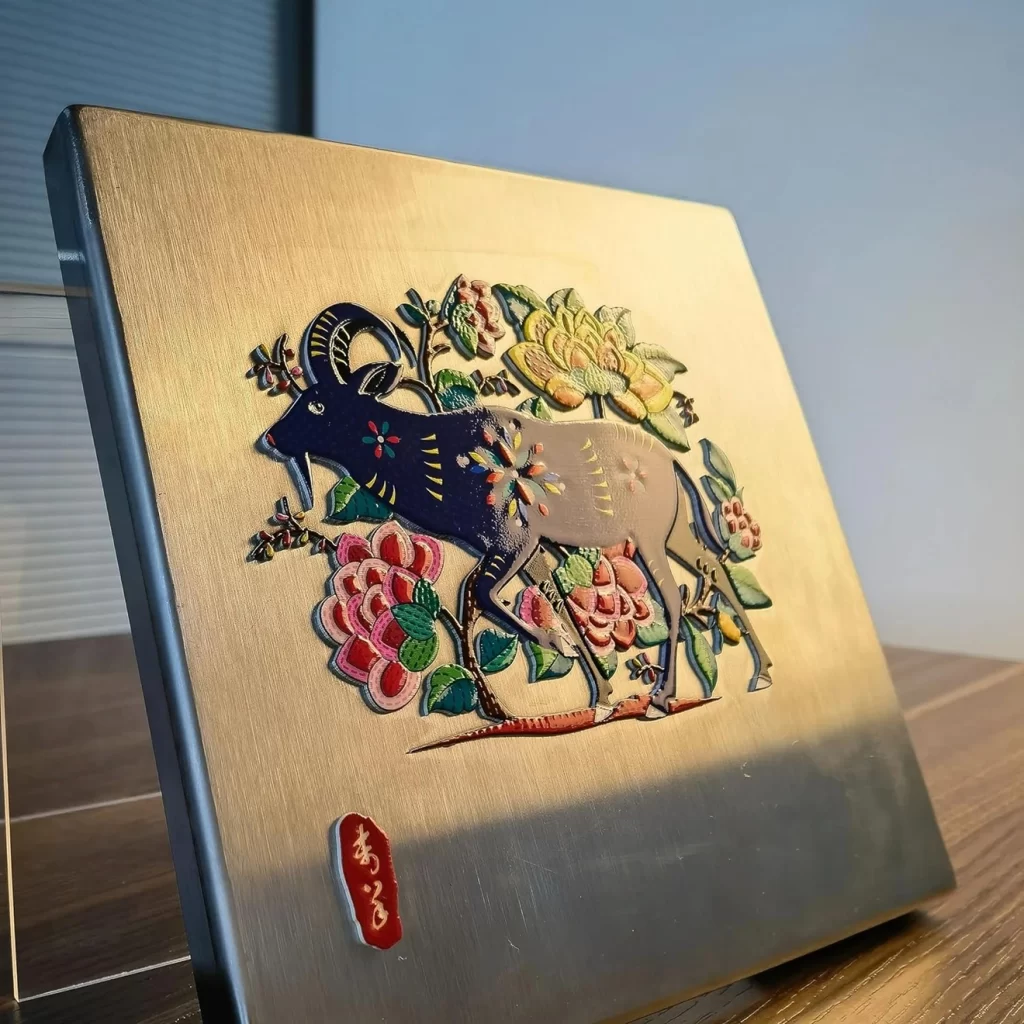

One of the highly appreciated benefits of this printer is it makes objects more waterproof, high-temperature resistant, ultraviolet resistant, and acid and alkali-resistant. These are renowned for their fight against fading, scratching, and other forms of damage. As a result long-lasting results are produced with a soft, glossy, and embossed look.

Eco-Friendly Printing

In today’s environmentally conscious time, this printer shines as a sustainable printing solution. Unlike traditional printing methods that often involve harmful chemicals and excessive waste, UV DTF printing employs eco-friendly UV-curable inks. These inks are not only vibrant and fast-curing but also eco-conscious reducing your carbon footprint while delivering exceptional results.

Enhanced Productivity

For enhanced production, the UV DTF doesn’t disappoint. With its rapid printing potential and minimal setup time, it gives you to take on more projects. The absence of screen preparation and drying times means faster production to meet tight deadlines without compromising on quality.

Application of UV DTF Printer

- Designers and clothing brands can create unique and personalized clothing items with ease.

- The printer is not only limited to fabric, you can print on cardboard, leather, glass, metal, and 3D objects.

- UV printer is perfect for printing on branding promotional items like posters, signage, bottle printing, tote bags, caps, and accessories.

- Customized home textiles, such as pillows, curtains, and bedding, are gaining popularity.

- Artists turn their designs into stunning textile art pieces for exhibitions and sale.

- Printer is used to create custom labels for products like food, beverages, and cosmetics.

Pros of UV DTF Printer

- The printer has versatile applications to print from fabric to leather, ceramics, canvas, metal, and more.

- UV printers use eco-conscious UV-curable inks that reduce environmental impact compared to traditional printing methods.

- Due to its efficiency, it ensures that the project deadlines are met and rapidly changing customer needs are promptly dealt with, saving both time and resources.

- The printer supports unparalleled clarity in prints with higher work efficiency.

- UV DTF printing takes simple steps to finish compared to other best DTF printers.

Cons of UV DTF Printer

- Operational costs are competitively high because you need both UV ink and transfer film.

- Regular DTF printer maintenance is a must for smooth working.

- Operating a UV printer effectively requires some training and experience to get outstanding print quality and color accuracy.

Future of UV DTF Printing

UV DTF printers undoubtedly outshine other printing methods. They offer a broad range of packaging and customization options, taking the industry by storm and gaining rapid popularity.

With significant potential to further transform businesses, they provide numerous opportunities for innovation. I’ll likely see more applications of this technology in the near future.

Conclusion

UV DTF printing is a smarter choice for the packaging and textile industry. Because of high-quality prints, versatility, eco-friendliness, and high productivity, UV DTF printers are booming in the market. As you go to buy this tool for your project, you’ll know how it’s getting popular in the printing line.

UV DTF printing represents a breakthrough in the printing industry. Its ability to deliver unmatched print quality, versatility across various materials, eco-friendliness, and enhanced productivity makes it a must-have tool for anyone in the printing industry.

Are you ready to set up your printing game? The UV DTF printer is your key to opening the door to endless opportunities. Printer technology is the future so let’s hold on to it and take our creativity up a notch today!