White Toner Printers for T-Shirts [Full Resource Guide 2025]

Are you a budding entrepreneur looking to start a white toner custom t-shirt or DTF printing business? Or you’re an established business owner aiming to expand your product line with high-quality, vibrant designs on darker fabric.

Regardless of your position, investing in a top-notch white toner printer is a game-changer. These innovative printers produce weedless full-color transfers on dark-colored and navy-blue textiles like t-shirts, sweaters, jackets, hats, and more!

It works smoothly for all sizes and even for single-shirt orders without any messy setup. Although it’s a perfect choice for garment decoration, you can do so much more with it. With the same printer, you can create full-color transfers for hard surfaces like keychains, photo panels, and wood signs.

In this guide, I’m going to give you an in-depth look at how white toner printer for t-shirts work, and key features you should consider while buying this equipment for your business.

Interested? Let’s start!

Table of Contents

What are White Toner Printers?

These specialized laser printer machines use dry white powder ink that is later fused onto the media. Have you ever tried crayons on a black piece of paper? You can’t see the image you’re coloring, can you?

It goes the same way when you transfer printed images onto dark fabric without a white underlayer. Your printed graphics need a white base layer, otherwise, colors will fade away against a dark background.

That’s where the use of a white toner printer for T-shirt customization comes in. It prints the full-color graphic on fabric and then prints a white base layer over it to show up other color toners brightly. The printer then prints the rest of the design, layer by layer, until the image is complete.

Thanks to its special adhesive feature, now you’re not limited to specific material or fabric. You can transfer prints onto cotton, polyester, blends, polypropylene, and more.

White Toner vs. Traditional DTF

Although traditional DTF printing has its advantages in textile printing, white toner printing is different from it. With its special advantages, businesses prioritize this printing technique. Let’s do a quick comparison of both printing techniques.

- White toner uses dry toner ink to print onto film while traditional DTF uses liquid inks to print onto film.

- White toner DTF uses a solid sheet of adhesive that is heat-pressed to the dry ink on the film. Traditional methods use a loose DTF powder adhesive that is shaken and poured over the whole print when the ink is wet.

- Both DTFs require heat to set the adhesive so it can adhere to the ink. Once cooled, the bond is cured and permanent, ready to be applied to the garment. The key difference is here the traditional DTF requires a separate oven to set the adhesive after it has been applied and shaken while white toner DTF is applied and set on a heat press in one step.

- Both DTF transfers are heat-pressed onto the garment, peeled, and then re-pressed to set the edges and finishes. The difference is traditional DTF is peeled cold or hot depending on the material being used, while white toner DTF is almost always peeled cold.

- White toner DTF printers are famous for their speed and simplicity. Because its laser technology sped up the overall process significantly. Once the file is transferred to the printer from the RIP program, the traditional DTF will take a few minutes to print, while the same transfer with a white toner DTF can be printed in seconds.

- Traditional DTF requires a power station or shaking machine, heat press, and oven, while a white toner DTF only needs a printer and heat press. That’s why regular maintenance is almost non-existent for white-toner printers.

How White Toner Printer for T-shirts work?

Here is a step-by-step guide on how to use a white toner printer to print a t-shirt:

Step #1: Create Your Design- The initial stage is to create a design using the computer program RIP. But it is not only about that, you can also think of using Adobe Photoshop and Illustrator. This design may well be in the form of texts, images, or both.

Step #2: Sending the Design to the Printer- Once the design is ready, it is sent to the white toner printer via a computer or a compatible device. The printer takes out the digital file and starts to print it on the T-shirt.

Step #3: Coating the T-shirt- Before running the T-shirt through the printing process, it is coated with a white powder to make sure that the ink adheres properly to the fabric. With this coating, your prints will have a sharp and strong mark.

Step #4: Printing the White Base Layer- The first job for the white toner printer is spreading white ink evenly on the selected area of the T-shirt. This white coating acts as the base for the following colors which are the most precise, especially on dark colors.

Step #5: Applying the Color Layers- Once the printer finishes the white layer, it then proceeds to apply the ink color layers as per the specified design. These colors are placed on the white base to produce a fantastic and detailed print of the t-shirt design.

Step #6: Heat Setting and Drying- The last stage in the printing process is to subject the T-shirt to heat to firmly set the ink. This process of heat setting assures the durability of the print even after several washes, maintaining the quality as well as the sustainability of the design. When the transfer paper is cooled down, don’t forget to peel it off. Your T-shirt is now ready to wear!

Pros and Cons of White Toner Printer

| Pros | Cons |

| Can print on a wide variety of fabrics and materials | Initial price is a little bit high |

| Can be applied to any color of T-shirt | Only compatible with PC |

| Printing speed is fast, you can print multiple garments in a short time | White toner is more expensive than regular toner |

| Easy to use, even for beginners | |

| No DTF white ink problems | |

| No maintenance is required |

Key Features to Consider While Buying a White Toner Printer

- Print Quality: The foremost consideration should be the print quality. Look for a printer that has high-resolution prints with flawless color vibrancy and accuracy. A model with advanced color management ability can significantly enhance the final output.

- Print Speed: Time is money, so do you want to consider it when buying a white printer? Of course yes! Efficiency is crucial, especially when dealing with bulk orders. Opt for a printer that strikes a balance between superior print quality and reasonable printing speed to meet the demands of your business.

- White Underprint: It’s the coolest feature to look for in a white toner printer. This is where you would reverse the order of the toner cartridge in effect having your white ink print on top instead of underneath the graphic being used for transfer printed media on or under the other side of the substrate (cardstock, poster, or window-cling). Being able to print directly onto the media like this expands your capabilities and allows you to offer more products to your customers.

List of Essentials White Toner Printing

Here’s a list of essential white toner printing supplies and consumables:

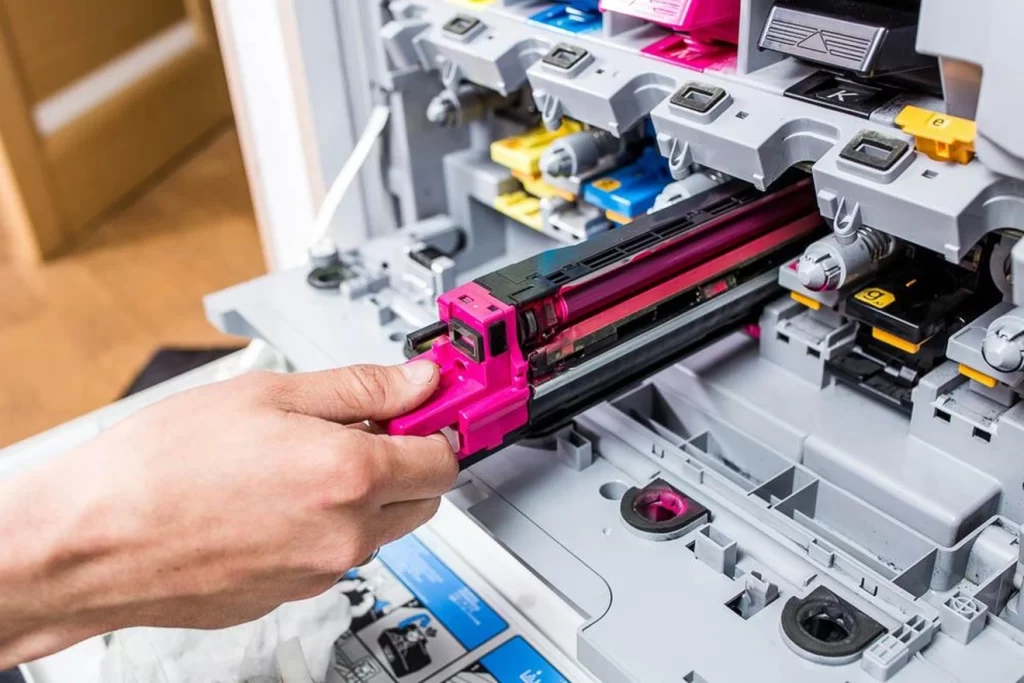

- White Toner Cartridges: The lifeblood of white toner printing, white toner cartridges contain the white toner powder used to create a base layer for printing on dark or transparent media. They tend to be more expensive than regular toner cartridges.

- CMYK Toner Cartridges: CMYK stands for Cyan, Magenta, Yellow, and Black. These cartridges provide the standard color palette used for printing designs on top of the white base.

- Transfer Paper: This type of paper is typically made of a heat-resistant material. It is used to design any print that is later on transferred onto the substrate.

- Heat Press Machine: A heat press machine is used to apply heat to transfer a design onto the substrate. It typically consists of a heated platen and a flat surface where the material is placed.

- Heat-resistant Tape: When you are working with heat transfer onto a substrate, there’s a high chance your design may slip. A heat-resistant tape is essential to secure transfer papers onto substrates during the process to prevent shifting and misalignment.

Why are the Toner Printers Important for T-shirts?

There’s been a problem with heat transfer printer since its inception: You can’t get a good-looking print onto a dark T-shirt or hard goods without there being prominently displayed along the entire perimeter. If you apply CMYK colors for regular color laser or inkjet, the color that comes out is very pale especially if the shirt is black.

Well, to my mind this is similar to painting a new color on the wall that has already been painted in black, red, or brown color. When you rub black with yellow paint you get a dull orange color instead of bright yellow- it is recommended that you should primer it first. White toner is recommended to be used as a base coat to be applied on the T-shirt transfers.

For this reason, sublimation transfers are possible only on light-colored (mainly white) one hundred percent synthetic T-shirts if you know what I mean – no white toner here, only polyester. However, with several white toner printers in the market, which one should you opt for?

The Bottom Line

White toner printers are perfect for printing customized T-shirts that have vivid colors and sharp details. They are simple to use and provide various benefits compared to traditional screen printing methods.

If you are interested in launching a custom T-shirt business or simply want an option to create your custom T-shirts at home, a white-toner printer will prove to be a valuable investment.